Flexible Packaging Testing Equipment and Fixtures

Thwing-Albert is the worldwide leader in manufacturing testing equipment for measuring the physical properties of flexible packaging materials. Our products include:

Universal Testing Machines

- VantageNX Universal Testing Machine: With the ability to test properties such as tensile strength, elongation, coefficient of friction (COF), puncture strength and more, our VantageNX Universal Testing Machine is one of the most versatile pieces of equipment we offer. Five different frame models are available to provide versatile and flexible testing capability.

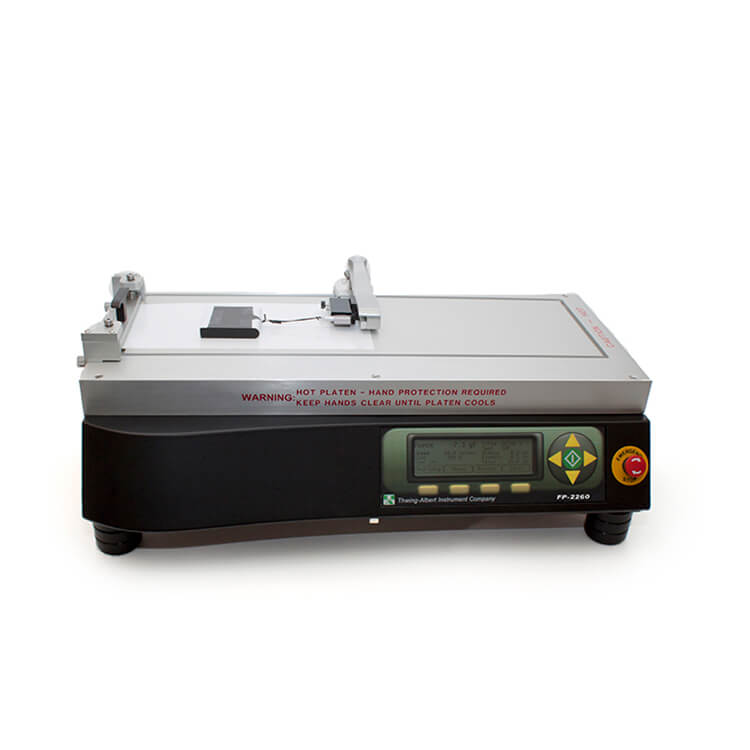

Friction/Peel Testers

- FP-2260 Friction/Peel Tester: Thwing-Albert’s FP-2260 Friction/Peel Tester offers the capability of measuring the coefficient of friction including static COF, kinetic COF and slide angle, while the peel mode can measure seal, bond and adhesion strength.

- Heated Platen FP-2260 Friction/Peel Tester: Our Heated Platen FP-2260 Friction/Peel Tester provides all the standard version features with the added ability to test at elevated temperatures.

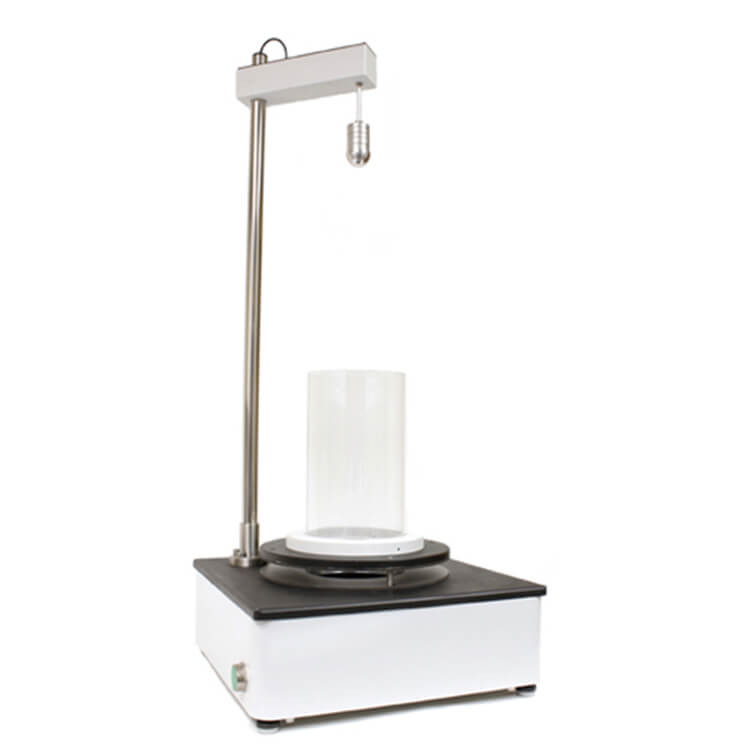

Impact Testers

- Spencer Impact Tester — ASTM D3420: Our Spencer Impact Tester is an accessory used on the Electronic Elmendorf ProTear to measure the dynamic impact resistance of sheeted material.

- Dart Drop Impact Tester — ASTM D1709: Our Dart Drop Impact Tester is an ergonomically designed, easy-to-use device that calculates the impact resistance of coated paper, plastic film and other flexible packaging materials.

Thickness Testers

- ProGage Thickness Tester: The ProGage Thickness Tester is a dead-weight micrometer designed to accurately measure the thickness of material used in flexible packaging including plastic film, paper and foil.

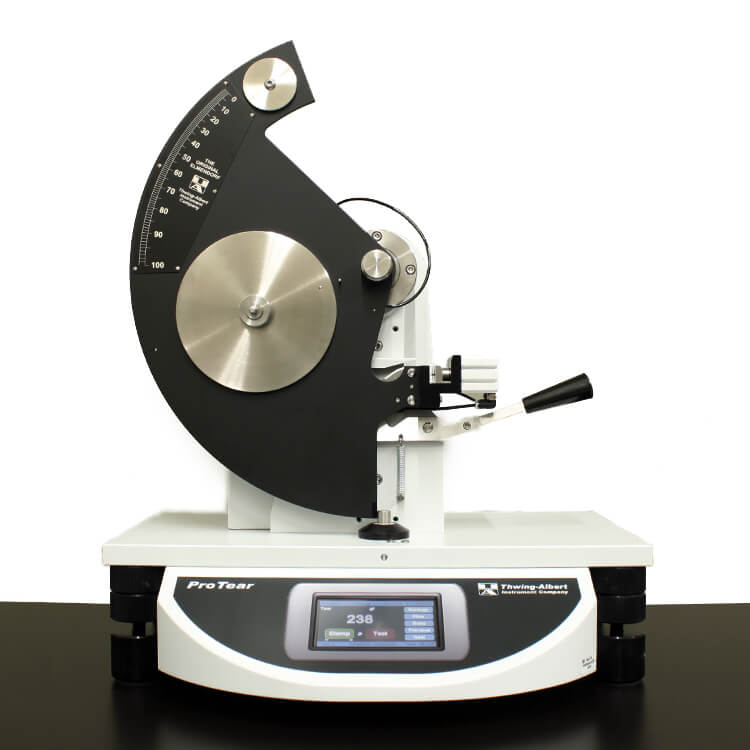

Tear Resistance Testers

- Electronic Elmendorf ProTear: Our Electronic Elmendorf ProTear is one of the most accurate machines in the industry for measuring the tear resistance of flexible packaging and various other materials.

Cutters

- JDC Precision Cutters (10-, 12- and 16-inch samples): JDC Precision Sample Cutters are among the most accurate sample preparation cutters on the market to prepare samples strips of an exact, defect-free width. This dedicated width cutter is available in widths between 1/8″ to 3″ and lengths of either 10, 12 or 16 inches.

- Alfa Cutters: The 240-15B and 240-7B Pneumatic Alfa Sample Cutters allow users to quickly prepare test samples for various packaging materials, such as plastics, cardboard and heavy papers.

Vapometers

- EZ-Cup Vapometers: The 68-3000, 68-3002 and 68-3003 EZ-Cup Vapometers feature lightweight aluminum cups and two neoprene gaskets with a Teflon seal. This design allows users to measure water vapor permeability with ease and without leakage.

Fixtures

- Film Blocking Test Fixture for ASTM D3354: Our Film Blocking Test Fixture is an accessory designed for use with either our VantageNX Universal Testing Machine or Model 2260 Friction/Peel Tester to measure the inherent blocking that occurs between two layers of plastic film in accordance with ASTM D3354

- Film Puncture Fixture (pneumatic): Our Film Puncture Fixture pairs with our universal testers to determine a material’s slow-rate puncture resistance.

CeraTek Heat Sealers

As a partner with SencorpWhite, Thwing-Albert offers CeraTek Laboratory Heat Sealers as valuable tools to create heat seals for materials used in flexible packaging. These sealers will duplicate the sealing conditions used on production lines so that samples can be tested for seal strength using either our VantageNX Materials Tester, QC-3A Materials Tester or Model 2260 Friction/Peel Tester. Applications include product, food and medical packaging and trays. Multiple designs feature heat, impulse, multizone and pass-thru options for flexible packaging and many other substrates.

Available models include:

Contact Thwing-Albert for Flexible Packaging Testing Equipment Today

Contact us to obtain a quote or learn more about how Thwing-Albert’s flexibility packaging testing equipment and services can benefit your operation.