Universal Testing Machines

Thwing-Albert offers several industry-leading universal testing devices for measuring the physical characteristics of paperboard.

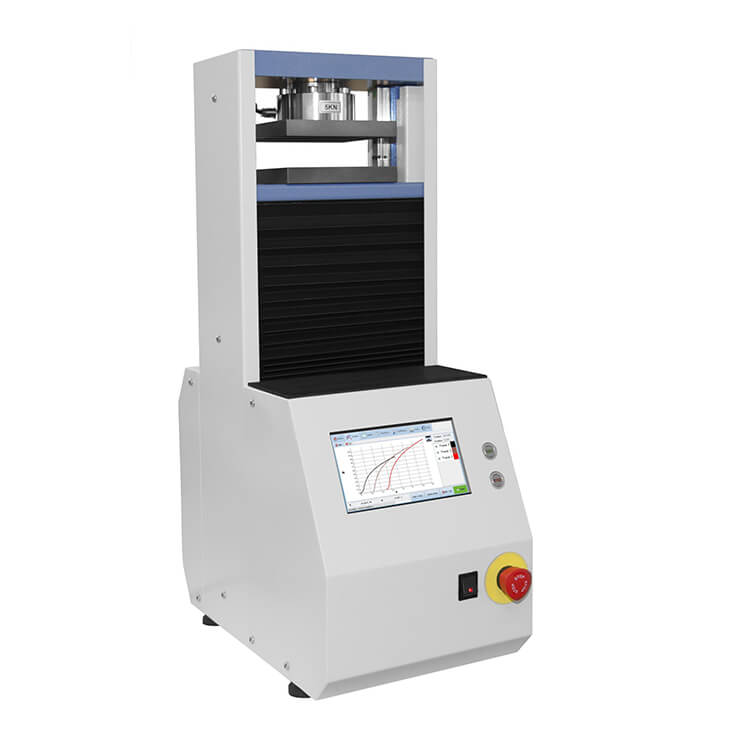

- VantageNX Tensile Testing Machine: The VantageNX Testing Machine is a powerful and versatile instrument that can conduct many tests for various paperboard grades, including crush, compression, bend resistance and puncture resistance.

- QC-3A Universal Testing Machine: Thwing-Albert’s QC-3A Universal Tester ensures the high-performance of the QC testing line with state-of-the-art software, an RS-232 interface and a precise digital load controller.

Peel, Tear and Abrasion Testing Equipment

Peel and tear testing are critical in paperboard performance for determining the effectiveness of the adhesives used in joints. Abrasion testing ensures the appropriate physical properties and the necessary amount of fiber shedding.

- FP-2260 Friction/Peel Tester: The FP-2260 offers multiple test modes to determine various physical properties, including the seal strength and peel characteristics crucial to the performance of paperboard products.

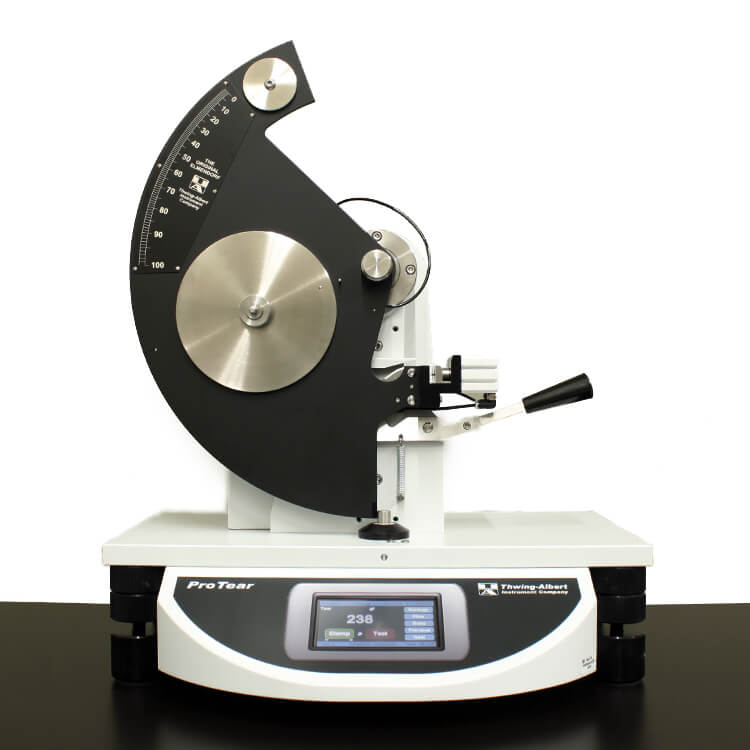

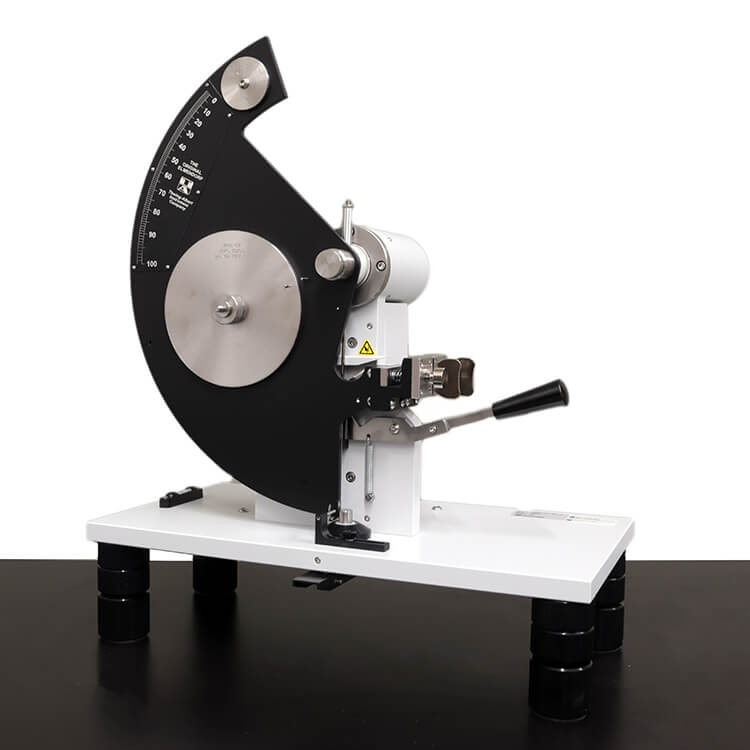

- Mechanical Elmendorf: The Mechanical Elmendorf is a manual device for measuring the tear resistance of paper and paperboard materials.

- Electronic Elmendorf ProTear: The Electronic Elmendorf ProTear provides the same functionality as the mechanical version with increased speed, efficiency and precision.

- Heavy Duty Electronic ProTear: The Heavy Duty Electronic Pro Tear offers the same benefits as our other Elmendorf models with increased testing capacities for materials having a greater resistance to tearing.

- Taber Abraser (1700/1750): The Taber Abraser mounts to a rotating turntable to measure abrasion resistance at multiple angles relative to the material’s grain or weave.

Bend Resistance, Score Quality and Compression Testers

Characteristics such as bend resistance, score quality and compression are critical factors for evaluating the performance of paperboard in sheet and packaging form.

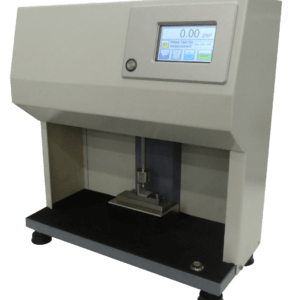

- 1270 PCA Score Bend and Opening Force Tester: The 1270 PCA Tester determines the force required to bend the paperboard at a defined score or open a flat paperboard carton.

- Bending Resistance Tester: The RL-BRT-A measures the stiffness and bending resistance of paperboard and other paper products.

- Score Quality Fixture TAPPI T829: Thwing-Albert’s Score Quality Fixture pairs with the 1270 PCA Score Bend Tester or the VantageNX Tensile Testing Machine to measure corrugated score quality according to TAPPI T829.

- TA3540 Deflectometer: The TA3540 Deflectometer pairs with other Thwing-Albert universal testing equipment to precisely measure positioning and deflection data for tests such as flexural bend.

- Short Span Compression Tester: The RL-SSC-A and SCT-21 Short Span Compression Testers efficiently and accurately measure paper and linerboard compression strength in accordance to TAPPI T826 and ISO 9895.

Burst and Crush Testers

Measuring paperboard’s burst and crush strength is vital for ensuring that paperboard and shipping containers have the necessary resistance against pressure and compression.

- Crush testers: The RL-CT-A and CT-21 crush testers are designed to measure the crush resistance of paperboard and corrugated materials. Available tests include pin adhesion, ring crush, flat crush and edge crush.

- Burst strength testers: The RL-BT-A, RL-BT-C and BT-21 are Mullen-type burst strength testers for paper, paperboard and corrugated materials.

Thickness and Internal Bond Testing Machines

Thickness and internal bond testing equipment ensure the necessary calipers of paperboard and the quality of the bonding between medium and liners.

- ProGage Thickness Tester: The ProGage Thickness Tester uses innovative features to accurately and efficiently measure the thickness of paperboard materials.

- VantageNX Z-Directional Tensile Tester: The VantageNX Z-Directional Tester measures the internal strength of paperboard and liner board bonding in accordance with TAPPI T541 and ISO 15754.

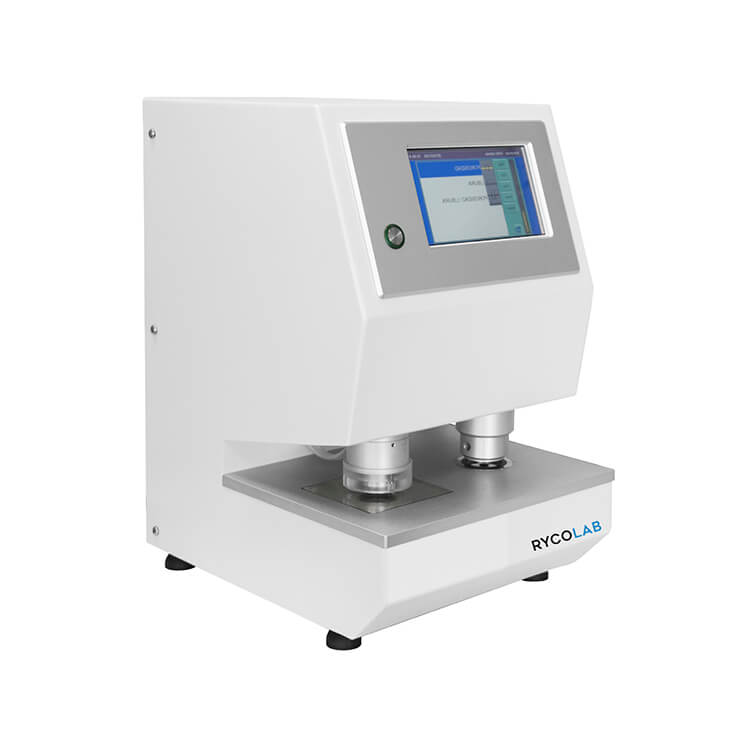

- Internal Bond Tester: The Rycolab RL-IBT-A uses a built-in digital display and microprocessor to determine the inner bonding strength of paperboard products in accordance with TAPPI T569 and T833.

Permeability and Absorption Testing Equipment

Because paperboard is a porous material, air permeability and liquid absorption play vital roles in determining structural quality.

- Bendtsen Roughness and Air Permeability Tester: The Rycolab RL-BRAPT-A Tester measures paperboard surface roughness and air permeability according to the Bendtsen method.

- Gurley 4340 Automatic Densometer & Smoothness Tester: The Gurley 4340 Tester measures air resistance, permeability and porosity of paperboard and other sheeted materials.

- Gurley Cobb Sizing Tester: The Gurley Cobb Sizing Tester measures the resilience or liquid absorptiveness of treated and untreated paperboard products.

- Semi Automatic Cobb Tester: The Rycolab RL-SAC-A determines the paperboard’s water and oil absorption capacity by measuring the amount of liquid penetrating the material.

Contact Thwing-Albert for Paperboard Testing Equipment Today

Thwing-Albert has been a global leader in manufacturing high-performance material testing solutions for over 120 years. We offer unparalleled customer service and technical expertise to help you find the most reliable, efficient and cost-effective equipment to meet your applications. Contact us today for a quote or additional product information.