Upcoming Shows…

More Events

2025-2026 Events

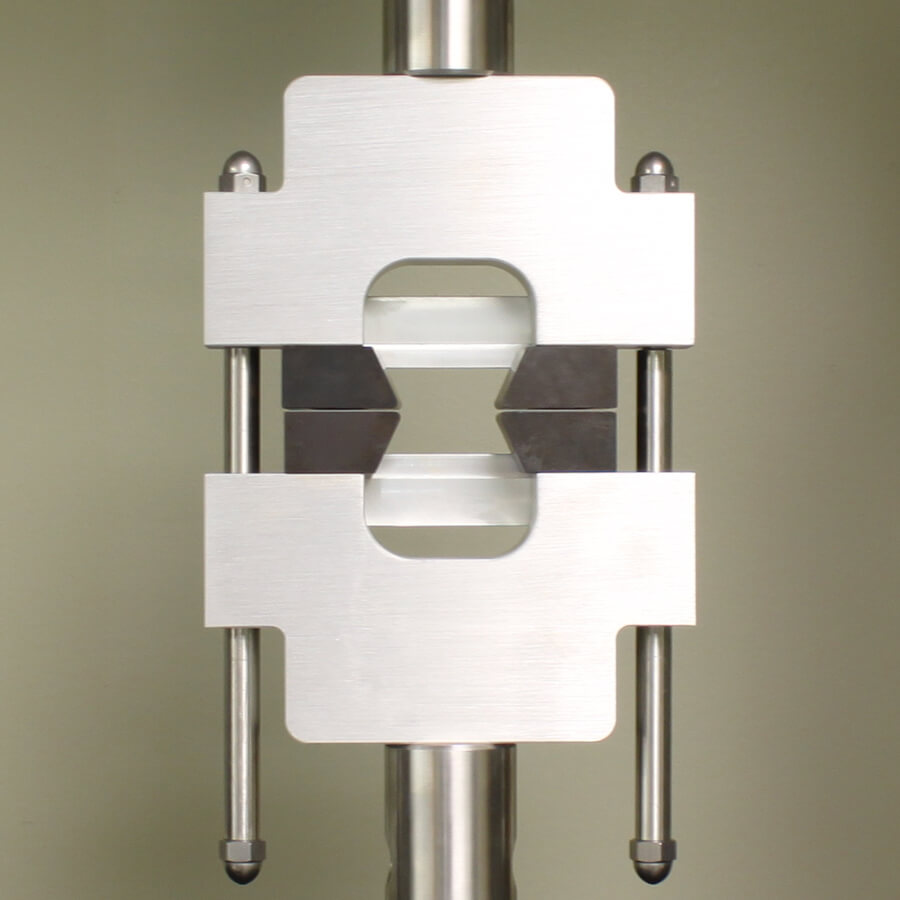

A typical tensile testing machine is composed of several basic components. A load cell, crosshead, grips, electronics and a drive system are the main elements of these types of testing frames. The apparatus is controlled by testing software utilized to analyze machine and safety settings, as well as to compare the performance of the samples against test parameters defined by testing standards.

A tensile test is used to determine how a material will react to an applied force and evaluate performance in a controlled testing environment. The test frame incorporates grips and fixtures to hold a sample and then run a specified test to determine a variety of characteristics such as yield strength, tensile strength, strain at break and additional material properties such as elasticity and deformation properties. The resulting data obtained as a result of the test are generally plotted on a graph and will show real-world performance characteristics.

Understanding a material’s tensile characteristics prior to its application is vital to predicting its fitness for use and its ability to perform as intended.

Among the machines Thwing-Albert offers for tensile strength testing are:

Some of our featured options for holding samples during tensile testing include:

We offer a complete line of other tensile tester grips and fixtures to provide added versatility and comply with a wide range of industry specs and standards. We can also build custom fixtures and grips for diverse testing applications. Review our tips for proper grip selection for insight on choosing the proper equipment for your specific tensile testing requirements.

Our MAP4™ Materials Testing Software is among the most versatile and accurate testing software on the market. Its versatility ensures compatibility with our full line of VantageNX tensile testers and other lines of equipment. Analyzing material is simplified with the software’s built-in library of industry standards.

Besides testing for tensile strength, the MAP4™software can measure properties like bursting strength, puncture resistance, compression and peel strength. Thwing-Albert provides a library of test methods designed around major industry standards like ASTM, ISO, TAPPI and more. Additionally, MAP4™provides the user with all the tools needed to create custom test methods based on their specific needs.

This software is compatible with Windows operating systems and includes free technical support for one full year.

To request more information about Thwing Albert’s Tensile Testing Frames or any of our other products, give us a call at 856-767-1000 or fill out our contact form today.