Upcoming Shows…

More Events

2025-2026 Events

The coefficient of friction (COF) fixtures are used to assess and measure the friction of paperboard and plastic materials. These fixtures are compatible with materials testing machines including the VantageNX Series Tensile Testers, the 1270 PCA Score Bend Tester, and QC-3A Universal Testing Machine.

The compression fixtures test the compressibility and compressive resistance of materials such as springs, aluminum cans, plastic bottles, and foam. Various testing fixture shapes are available to accommodate different sample types and testing standards.

Our deflectometers measure the deformation or deflection of materials using flexural and compression strength tests. The fixture can be positioned above or below the test specimen to accommodate the specific test procedures.

Our drum rubber grips — or eccentric roller grips — are designed to hold flat samples of materials such as general polymers, plastics, and rubber. These materials typically have a high degree of elongation.

Extensometer grips characterize strain on materials under stress to evaluate their change in length. This instrument supports precise measurements, as higher or lower load values do not affect strain measurements. These grips are compatible with VantageNX Universal Testing Systems and MAP4 software.

Our finch wet strength fixtures assess the wet tensile strength of towel and tissue material samples. Options include 1-inch and 3-inch models.

Our point bending fixtures test the flexural rigidity of samples. The grips determine material properties such as flexural strength, flexural yield strength, flexural modulus and stiffness.

Mechanical vise grips assist with general tensile strength testing for sheet materials such as plastics, fine metals, paper and textiles. Various grip insert widths for low-, medium- and high-capacity applications are available.

Tensile strength testing for rigid plastics, metals, composites and other high tensile strength materials requires mechanical wedge action grips. As the sample is stressed, the spring-loaded jaw applies more clamping force.

Peel fixtures test the adhesive properties of pressure-sensitive labels, tapes and adhesives. These fixtures peel the tape from its substrate at a specific velocity and angle.

Our vise-clamping and spring-loaded pincer grips are used in high-strength applications requiring high levels of clamping force. Technicians can set the clamping pressure exerted on the specimen.

Pneumatic grips allow for quick sample insertion while providing uniform contact pressure. Use these grips to test tissue, textiles, nonwovens, films, paper, tapes, and other sheet materials. Choose between smooth, rubber-covered or serrated surfaces on 1-inch, 2-inch and 3-inch grip inserts.

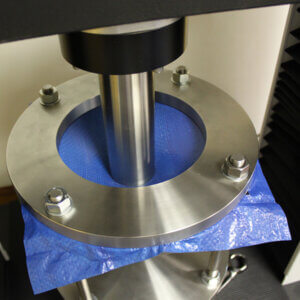

Puncture and burst fixtures measure a material’s ability to resist puncture. The sample clamp holds the material in place, and a penetration probe attempts to puncture the sample. Use these fixtures with nonwovens, geotextiles and membranes, textiles, paper tissue and films.

These bollard grips test yarn, rope, wire, cord and other flexible materials. They’re designed to hold flat, round samples securely to ensure test results are accurate and repeatable.

Our vacuum fixtures use vacuum power to hold uniquely shaped package samples and fragile materials securely. No grips, clamps or adhesives are required.

We have come across the need to develop special application fixtures for unique test setups with the VantageNX Tensile Strength Tester or other systems. Customers can rely on our team to help design the right option to hold the materials in order to capture the best analysis for the application.

Thwing-Albert is a leader in instrumentation for tensile strength testing with over 120 years of experience. Browse our testing fixtures and grips categories, and contact our team online for more information or a free quote.