Peel resistance evaluates the strength of the bond. Some types of bonds must be breakable at a low force, whereas others must withstand tougher conditions. Testing instrumentation ensures the bond functions as expected in its end-use application.

The testing equipment for measuring peel strength at Thwing-Albert includes 90 Degree, 180 Degree, T-Peel, and other applications to evaluate adhesive properties of materials such as seals, pressure-sensitive tapes and labels. Depending on the material and application, peel testing can simulate actual product use and be tested at various peeling angles.

Peel Resistance Testing Equipment

Thwing-Albert has the following equipment for testing peel resistance:

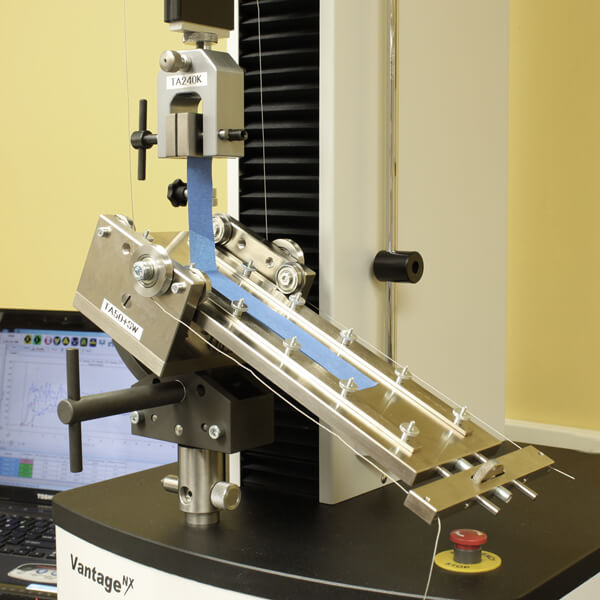

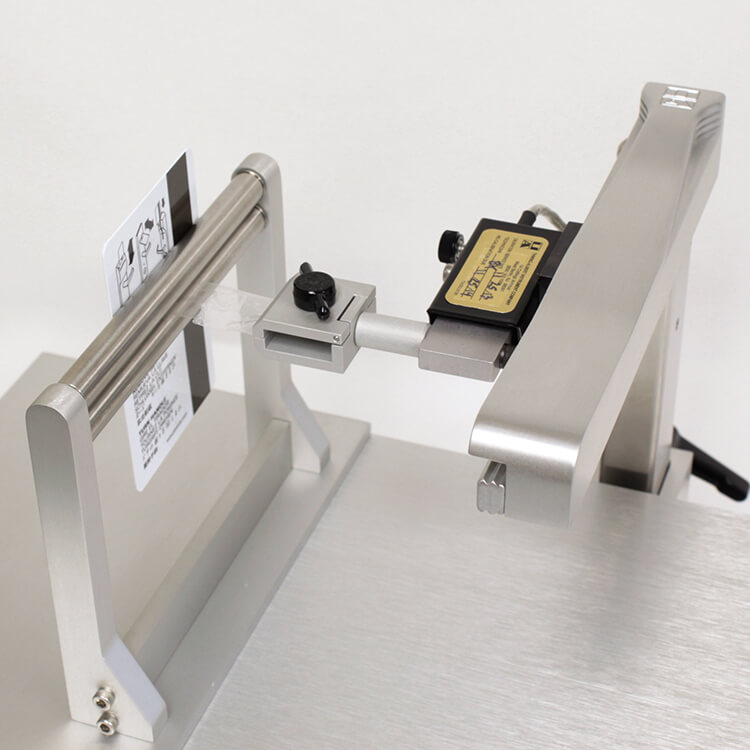

VantageNX Universal Testing Machine and Angled Peel Fixtures

The VantageNX Universal Testing Machine (UTM) completes material testing needs for peel strength and other types of testing. It is compatible with flexible packaging, tissue paper, paper, textiles, paperboard, plastic film, food packaging and more. Available in capacities of 1 kN, 2 kN or 5 kN. Various grips and fixtures are available to set up the VantageNX UTM for these tests.

Adhesion Testing Fixtures

- 180 Degree Peel Fixture: This peel fixture tool tests the strength of an adhesive at 180 degrees. One end of the sample is adhered to the plate while the other end is clamped. The fixture peels the sample from the plate to measure its strength.

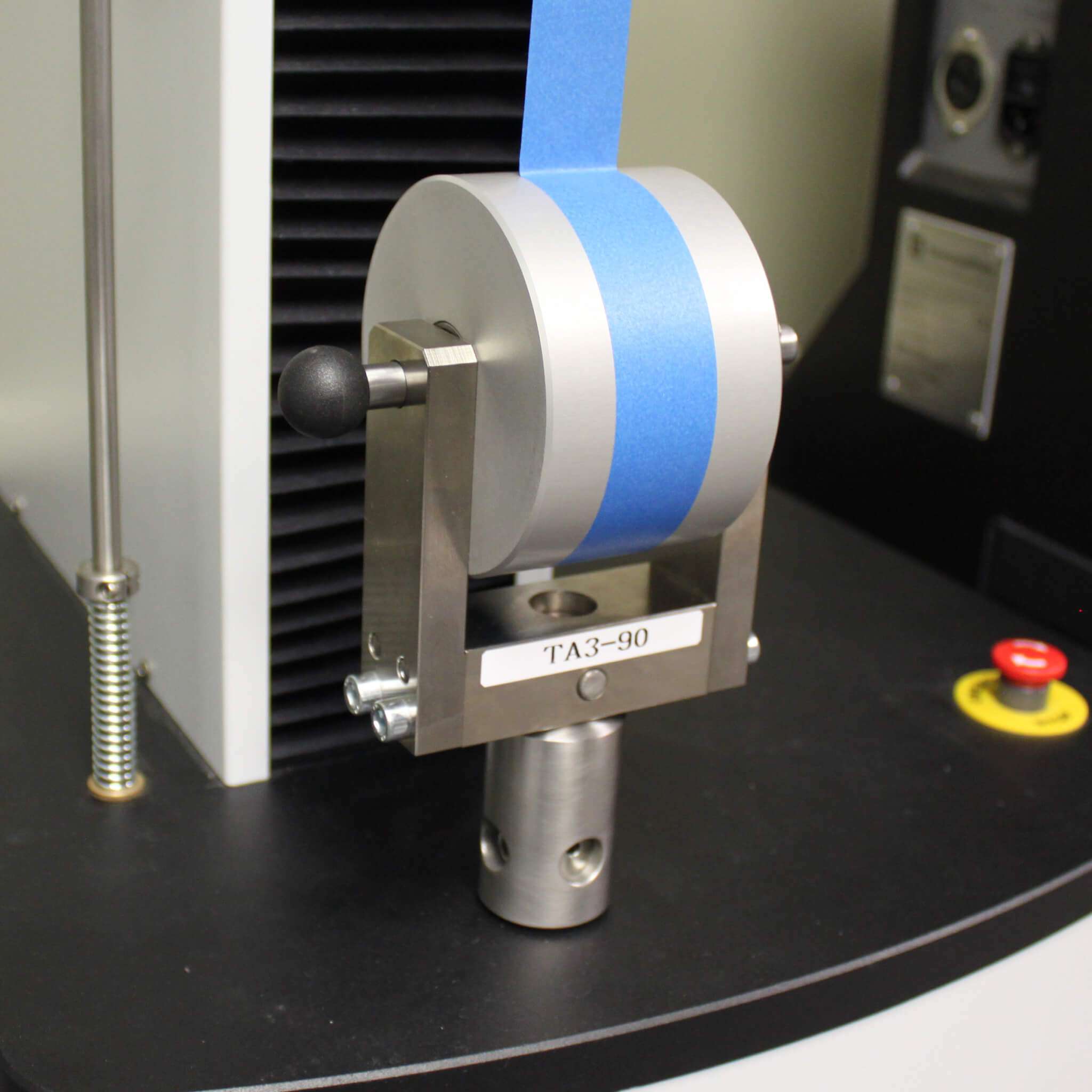

- 90 Degree Peel Fixture: The 90 Degree Peel Fixture is a fixture for testing peel strength in the VantageNX Tensile Tester. It uses a moving sample table to measure peel force at a 90-degree angle.

- TA50 Variable Angle Peel Test Fixture (10 kN): The TA50 peel test fixture measures bond strength at a consistent angle peel. Its maximum load is 10 kN.

- German Wheel Peel Fixture: The German Wheel Peel Fixture tests adhesion and bond strength on tapes, foils, plastic, laminated release coatings, adhesive-backed films and foils, and paper films.

- Package Seal Strength Fixture: The package seal fixture tests cup peel and tray peel to mimic real-world applications in food and medical settings. The clamping system holds the sample while the fixture grip conducts testing at various angles.

Friction Testing Machines

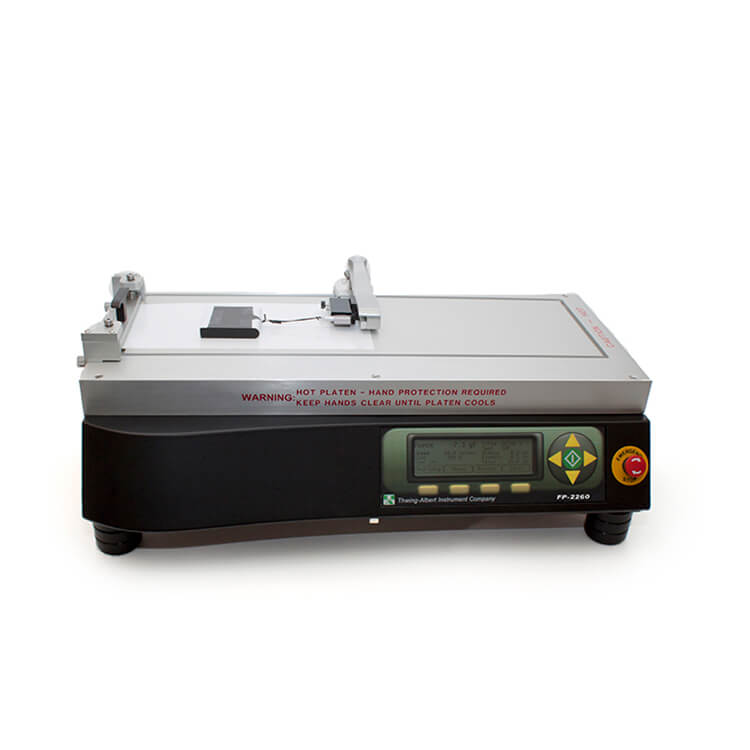

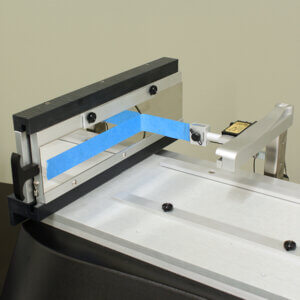

- FP-2260 Friction/Peel Tester: The FP-2260 tester conducts T-peel, 90-degree and 180-degree peel tests on packaging, adhesive, paperboard, label, paper and film materials. The results identify the peel properties. Up to 128 instances of peel test results data can be stored in the system for later review. The load cells are interchangeable.

- Heated Platen FP-2260 Friction/Peel Tester: The heated platen peel tester conducts peel testing at elevated temperatures ranging from 70 degrees F to 350 degrees F. This type of testing is ideal for plastic film, packaging, label and adhesive materials.

Optional Fixtures:

- T-Peel Fixture is available for the FP-2260 and is designed to meet ASTM D1876 the Standard Test Method for Peel Resistance of Adhesives.

- Seal Strength Fixture can be added to meet ASTM F88 Seal Strength Tests using either mechanical or pneumatic clamps.

- 90 degree Peel Fixture for the FP-2260 allows the machine to be configured to meet a 90 degree peel test.

- Tray Peel Fixture for FP-2260: The tray peel fixture is a specialized fixture to hold a rigid tray and test seal strength. The sample loading area can fit various sizes. Compatible with the FP-2260 Friction/Peel Tester.

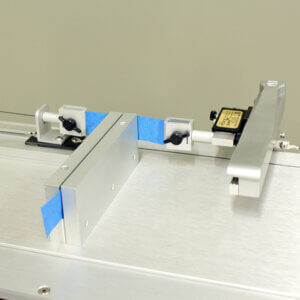

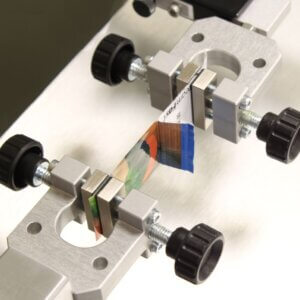

- Delamination peel fixture measures the strength required to separate the adhesives between the laminate and card in credit, identification and other cards. It is intended for use on the FP-2260 Friction/Peel Tester. The 2260 machine can meet various applications, including 90-degree, 180-degree and T-peel testing. The fixture complies with ISO 10373 testing standards and maintains a 90-degree angle during testing. The force required to separate the adhesive bond is measured and recorded.

Weighted Rollers

- FINAT Weighted Roller: The FINAT Weighted Roller conducts peel testing and sample preparation. The roller comprises a steel core and durometer silicone rubber. The handle legs extend past the roller circumference for protection. Different weights are available to meet FINAT Standard 2.1.

- PSTC/ASTM Weighted Roller: The PSTC/ASTM Weighted Roller meets peel testing and sample preparation standards by the Pressure Sensitive Tape Council (PSTC) and the American Society for Testing and Materials (ASTM). It has a steel core with durometer silicone rubber to apply even pressure across the tape.

Choose Thwing-Albert for Your Peel Resistance Testing Needs

Thwing-Albert is an industry leader with more than 120 years of experience. Whether you’re involved in product development, quality control, or research, our peel testers provide the precision and reliability you need. Contact our team today for a free quote or more information about our peel-resistance testing equipment.