Description

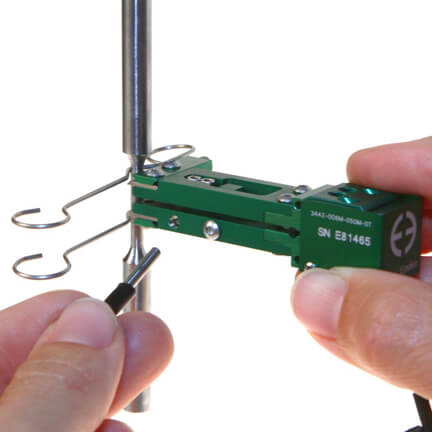

The TA3442 Extensometer has a small profile and is lightweight, ideal for evaluating the strain of materials including wire, sheet materials to meet ASTM and ISO standards.

This extensometer is designed to have very low operating force with minimal specimen influence and will fit in the limited space between grips that are typical with small test samples. Gauge lengths can be as short as 3 mm or as long as 50 mm.

Features:

- May be left on through specimen failure.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Gauge length pin helps set gauge length accurately for all gauge length configurations.

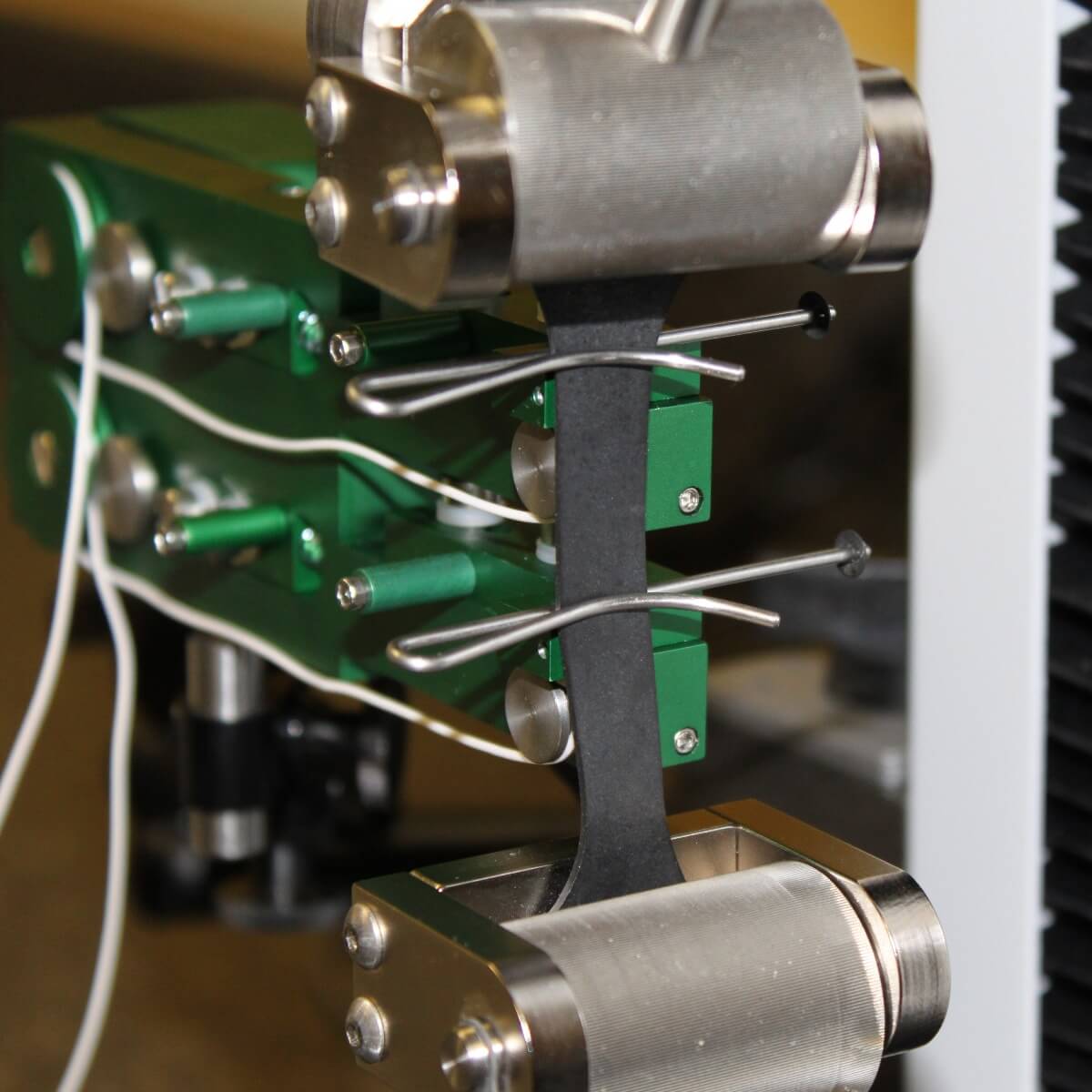

- All models can measure in both tension and compression and can be used for cyclic testing.

- Mechanical overtravel stops in both directions.

- Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

- Gauge length adapter kits enable configuration of multiple gauge lengths with one extensometer.

- Replaceable arms and spacers for ease of repair.

- High and low-temperature options extend operation from as low as -270 °C to +200 °C (-454 °F to +400 °F).

- Includes a Shunt Calibration System for on-site electrical calibration.

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V nominal, depending on model

Linearity: ≤0.15% of full-scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

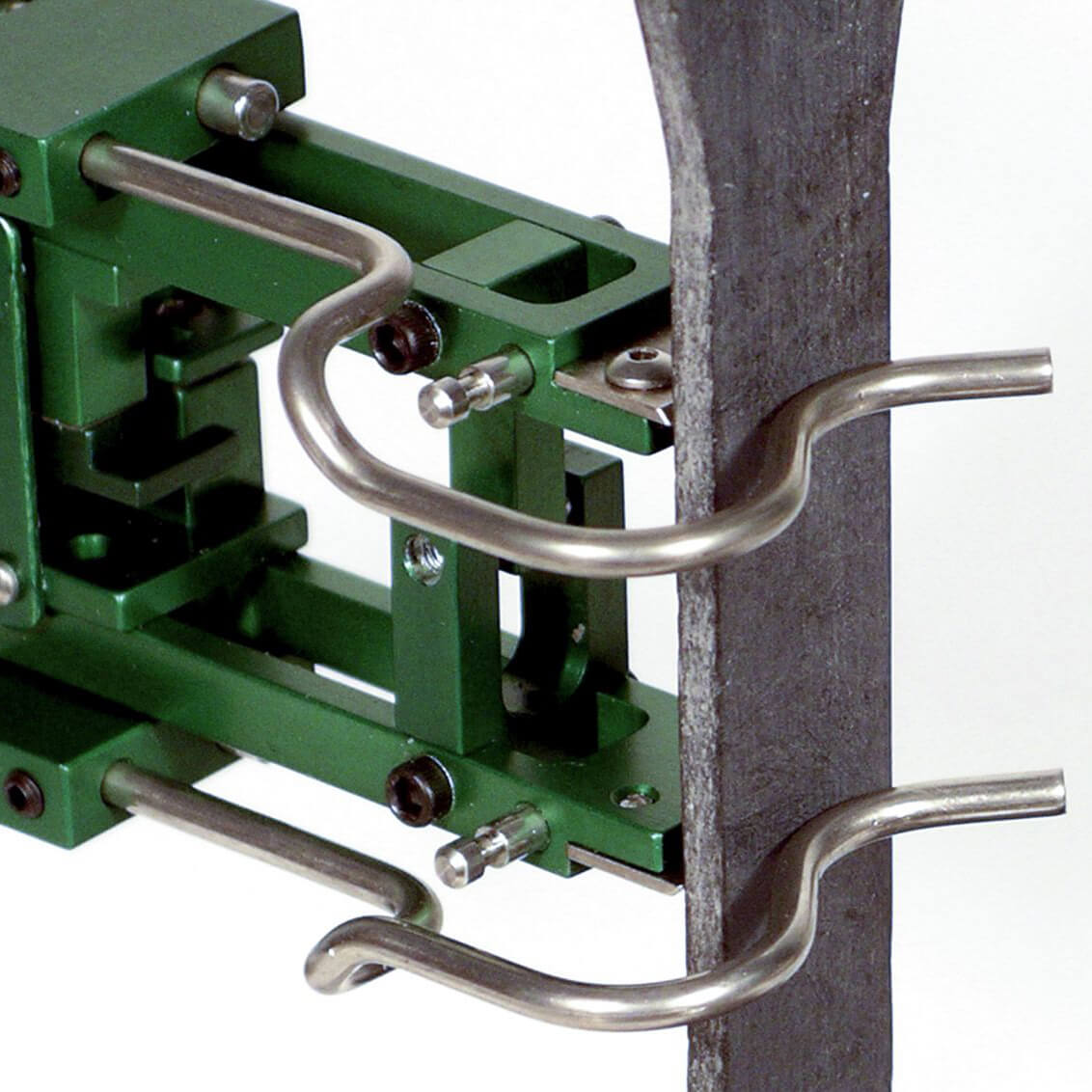

Standard Quick Attach Kit: Fits round samples up to 13 mm (0.5 inch) diameter and flats up to 13 mm thick by 15 mm wide (0.5 inch by 0.6 inch); attach to larger specimens using rubber bands or springs (included)

Operating Force: 10 to 20 g typical

Gage Lengths:

mm #

3.0 mm -003M¹

4.0 mm -004M¹

5.0 mm -005M¹

6.0 mm -006M

8.0 mm -008M

10.0 mm -010M

12.0 mm -012M

12.5 mm -0125M

20.0 mm -020M

25.0 mm -025M

50.0 mm -050M

Measuring Range:

Extension #

-005M ±0.5 mm

-010M ±1.0 mm

-020M +2.0 mm/-1.0 mm

-025M +2.5 mm/-1.0 mm

-050M2 +5.0 mm/-1.0 mm

-100M2 +10.0 mm/-1.0 mm

-125M2 +12.5 mm/-1.0 mm

Common Industry Standards:

- ASTM class B-1 requirements for accuracy for gauge lengths ≥6 mm and class B-2 for ≤5 mm. (A test certificate is included)

- ISO 9513 class 0,5 (test certificates are available upon request)