Adhesion Testing Equipment

Thwing-Albert has a vast selection of equipment for testing adhesion strength, including:

Universal Testing Machines

- VantageNX Tensile Testing Machine: The VantageNX Universal Testing Machine (UTM) can test the coefficient of friction, tensile, puncture strength and seal strength. Various fixtures and grips are available to set up this UTM for different tests.

- QC-3A Universal Testing Machine: A cost-effective tensile tester, a QC-3A UTM is a flexible testing platform. It can test peel analysis, coefficient of friction, compression and tensile.

Fixtures & Grips

- 180 Degree Peel Fixture: Perform peel tests adhering to ASTM D3330 and other industry standards with the 180 Degree Peel Fixture. The sample adheres to a stainless steel plate, and the upper grip peels the sample off the plate to measure strength.

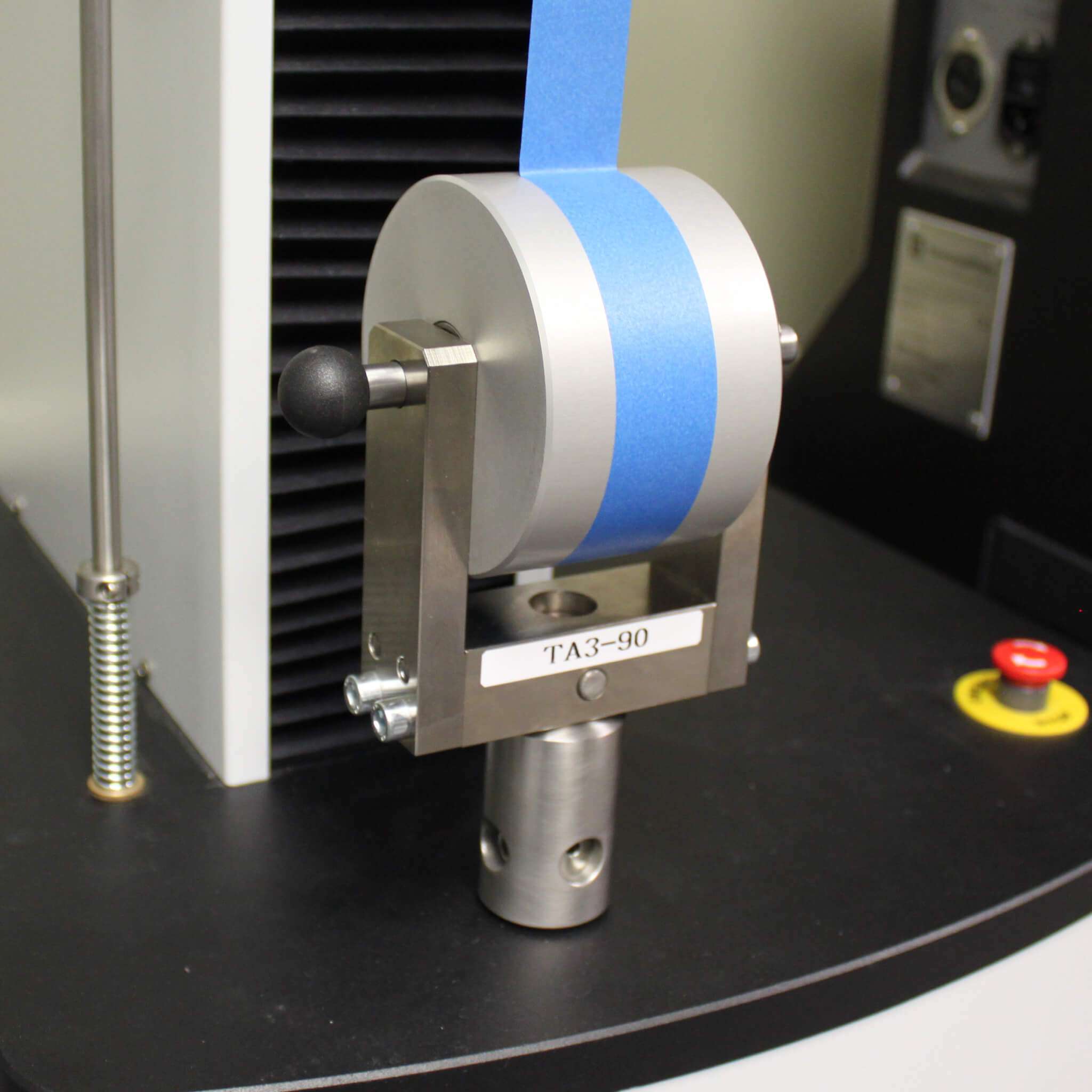

- 90 Degree Peel Fixture: The 90 Degree Peel Fixture is a Vantage Tensile Tester capable of measuring peel force at a 90-degree angle. It meets ASTM D6862 and ASTM D6252 standards.

- Variable Angle Peel TA50 Variable Angle Peel Test Fixture (10 kN)

This fixture is used to measure the bond strength. The sliding table provides a steady movement to maintain a constant angle peel (the peel point remains at the center).

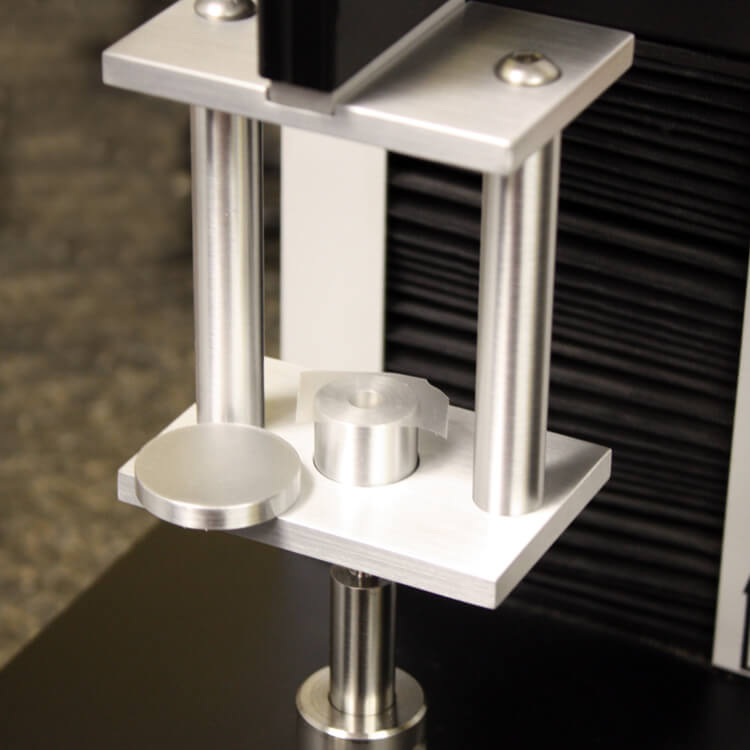

- Package Seal Strength Fixture

The Package Seal Strength Fixture is designed to use a vacuum powered clamping system to hold unique samples to test the seal strength for a variety of applications including cup peel, tray Peel, lid removal, seal removal, and seal strength.

- German Wheel Peel Fixture

The German Wheel Peel Fixture tests adhesion and bond strength for adhesive-backed foils and films. It complies with DIN 53357.

- Heated Platen (225-3024)

The 225-3024 Heated Platen measures peel strength analysis and coefficient of friction up to 350 degrees F to assess the effects of temperature on these properties.

Peel Testing Machines

- FP-2260 Friction/Peel Tester: The FP-2260 Tester evaluates seal strength and peel strength including 180 degree, 90 degree, T-peel and delamination when configured with the proper setup.An optional heated platen is available to quantify the affect of elevated temperatures may have on adhesive. Another specialty peel option includes the tray peel fixture for testing the seal on trays for food and medical uses. The additional fixtures allow his machine to be versitile and powerful for testing adhesion. This benchtop unit is ideal for laboratories and production floors.

Heat Sealers for Sample Preparation

- CeraTek ASL/1 Heat Sealers (12″ & 24″): The CeraTek ASL/1 Heat Sealer features an open-back frame with lower and upper heated jaws. It conforms to ASTM F2029.

- CeraTek Blister Heat Sealer TA808/1: The CeraTek Hot Die Blister Heat Sealer is pneumatically operated and designed for experimentation and quality control applications. Accurate testing can be done with precise control over sealing time and pressure.

- CeraTek AS/2 Heat Sealers (12″ & 24″): Our CeraTek AS/2 Heat Sealer features an open-back frame and external output ports. It is compliant with ISO 11607.

- CeraTek TA24-ASG/1 Heat Sealer: The CeraTek TA24-ASG/1 Heat Sealer features eight temperature zones on the upper heated jaw, each independently controlled.

- CeraTek P/3 Pass-Thru Heat Sealer (12″ & 24″): Our tabletop unit CeraTek Precision Pass-Thru Heat Sealer is designed for precise sealing. It’s capable of lateral and front-to-back pass-through for sealing at various depths.

- CeraTek TA4-GL/1 Heat Sealer: The CeraTek TA4-GL/1 Heat Sealer has four sealing zones and a four-zone gradient hot bar.

Weighted Rollers for Sample Prepration

Sample preparation is important to test results, there are various rollers available to help meet standards including ASTM D3330 / ASTM D3330M, FINAT Test Methods, and PSTC Appendix B.

- FINAT Weighted Roller

This weighted roller is available in different weights to meet FINAT Standard 2.1. Industry Standard for peel testing applications and sample preparation.

- PSTC/ASTM Weighted Roller

This weighted roller is available in different weights to meet PSTC and ASTM Industry Standards for peel testing applications and sample preparation. PSTC/ASTM Hand Roller

Contact Thwing-Albert to Get Adhesion Testing Equipment

Thwing-Albert is a leader in professional adhesion testing equipment, with over 120 years of industry experience. Our machines reliably evaluate the physical properties of adhesives, benefitting your operations with dependable results. Contact us to learn more or get a free quote today.