PackExpo International 2026 – Chicago, IL

October 18-21

Booth LU-8506

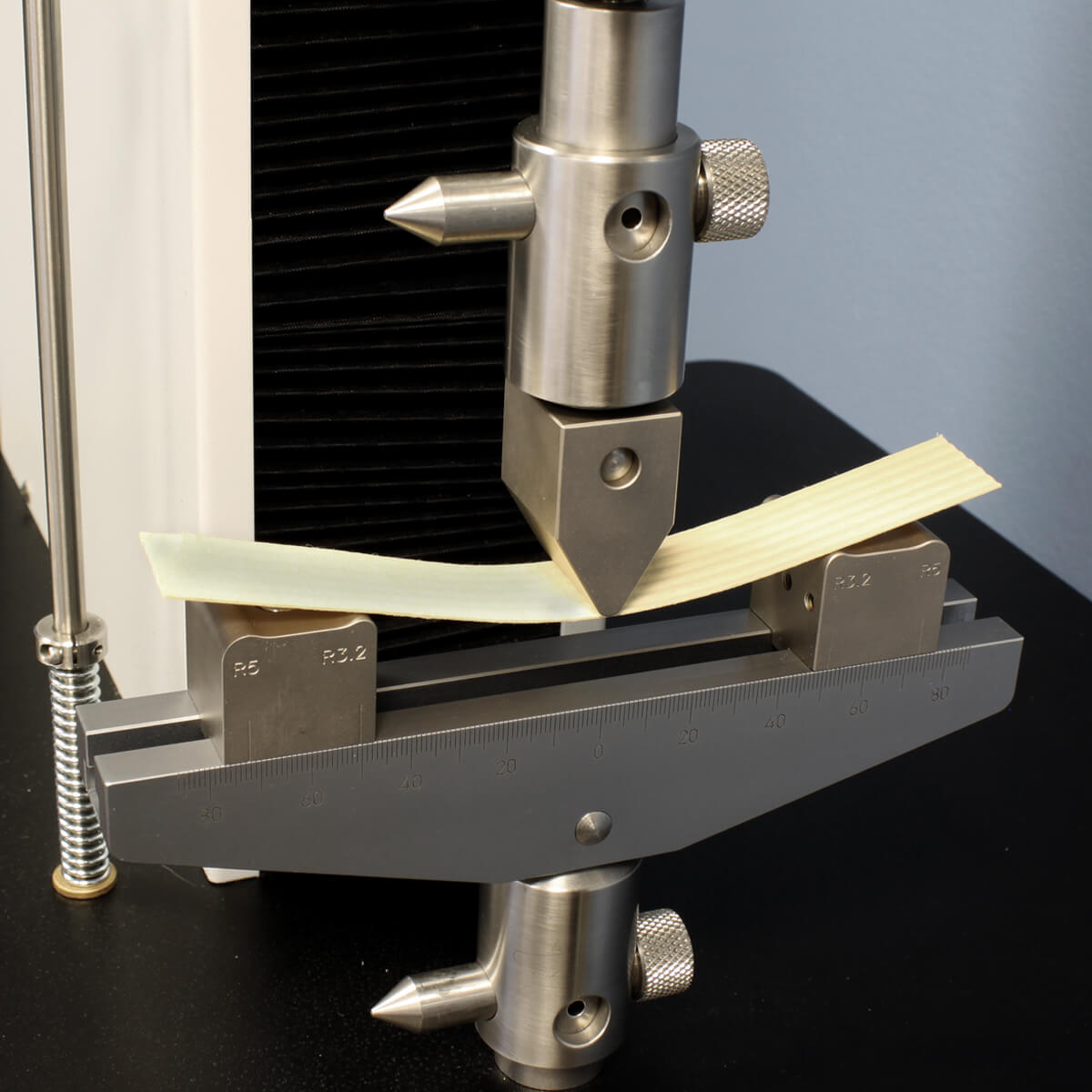

Flexural strength is critical when working with rigid to semi-rigid substrates such as plastics, metals, ceramics, composites, wood, laminates and similar materials. Flexural strength measures the maximum load-bearing capacity of a specific material before it sustains permanent damage. Flexural strength testing is instrumental for determining the extent to which a sample can resist breakage when bent.

October 18-21

Booth LU-8506

September 15-17, 2026

Booth 3603