PackExpo International 2026 – Chicago, IL

October 18-21

Booth LU-8506

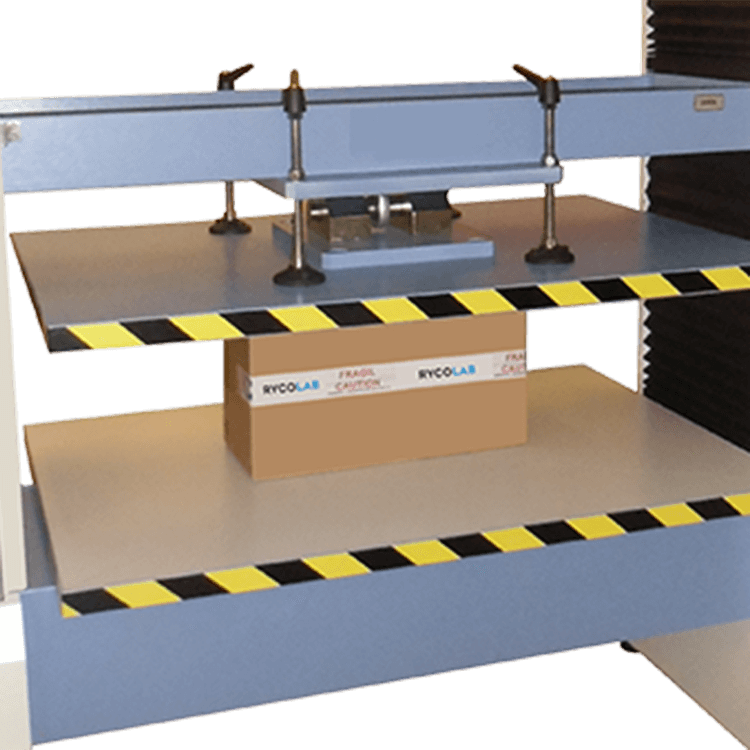

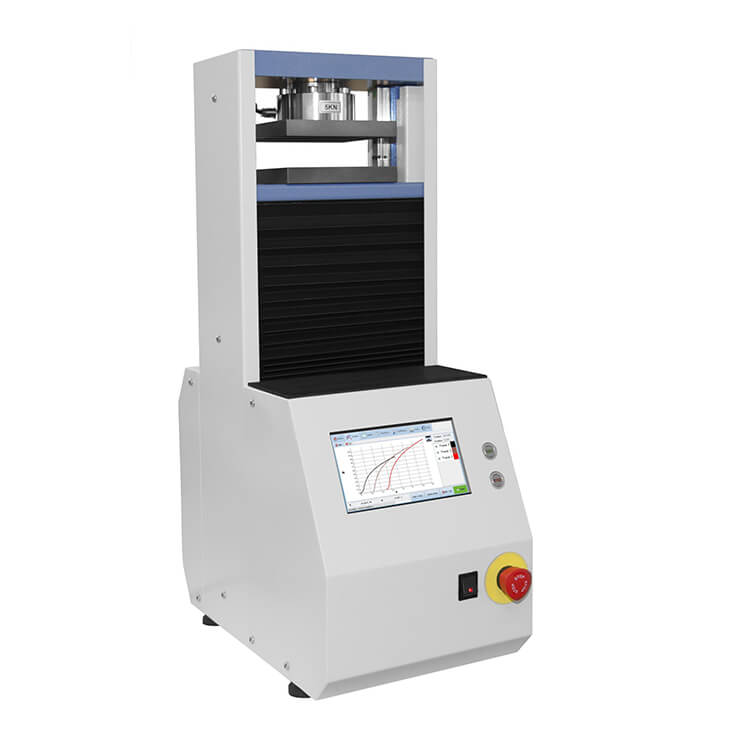

Equipment for testing crush resistance compresses a sample until it collapses or deforms. This measurement is compared to the load limit.

Thwing-Albert offers testing equipment for measuring crush strength in corrugated cardboard and other packaging materials. Our instrumentation adheres to leading industry standards.

October 18-21

Booth LU-8506

September 15-17, 2026

Booth 3603