Universal Testing Machines

Thwing-Albert supplies several universal testing machines for measuring a broad range of properties for various medical materials.

VantageNX Tensile Testing Machine: The VantageNX Tensile Testing Machine is one of the industry’s most versatile and powerful testing tools, capable of performing a comprehensive range of tests. These include seal testing for medicine cups, blister pack strength, stiffness of a needle and how much force it takes to open a package that will be used during critical medical procedures. Complex motion control, along with comprehensive data analysis, is accomplished through the use of our MAP4 Materials Testing Software.

QC-3A Universal Testing Machine: The QC-3A Testing Machine maintains the high standards of the QC product line while adding the functionality of a digital load controller, an RS-232 interface and a built-in testing interface for easy testing with consistent results. The simplified interface allows for basic tensile, peel and seal strength testing, along with coefficient of friction.

Adhesion and Bend Resistance Testing Machines

Adhesion and bend resistance tests determine the effectiveness of adhesives, cohesives and other components that are vital to material structure.

FP-2260 Friction/Peel Tester: The FP-2260 Friction/Peel Tester features various test modes to measure physical properties such as coefficient of friction (COF), peel properties and seal strength for a variety of materials.

1270 PCA Score Bend & Opening Force Tester: The 1270 PCA Score Bend & Opening Force Tester can measure the forces required to bend or open paperboard products — qualities that are critical for determining packaging performance.

Package Seal Strength Fixture: The Package Seal Strength Fixture holds samples with a vacuum-powered clamp to test the seal strength of various packaging products.

Tray Peel Fixture for FP-2260: The Tray Peel Fixture pairs with the FP-2260 tester to measure the seal strength properties of rigid trays.

Heat Sealer Equipment

High-quality heat sealing plays an essential role in materials used in medical applications, such as the performance of hermetic sealing on bags and pouches. Laboratory heat sealers provide a means to simulate production sealing parameters to optimize material performance.

CeraTek ASL/1 Heat Sealers (12″ & 24″): CeraTek ASL/1 Heat Sealers contain an open-back frame with independently controlled upper and lower jaws, a digital timer, temperature controller, surface-mounted thermocouples, dual-action cylinders and electronic timer activation. 110-volt, 60 Hz or 220-volt power options are available for 12-inch and 24-inch models.

CeraTek AS/1 Heat Sealers (12″ & 24″): CeraTek AS/1 Heat Sealers feature an open-back frame that allows for both lateral and front-to-back pass-through capabilities. A cycle-hold mechanism lets the user engage a locking tool to keep the jaws together at the end of a cycle. The standard device includes a 1-inch wide, flat upper sealing die.

CeraTek AS/2 Heat Sealers (12″ & 24″): CeraTek AS/2 Heat Sealers offer many of the same features as the AS/1 model, plus a programmable pressure alarm with a digital gauge and an inline transducer to monitor pressure. The AS/2 also contains multiple output ports for calibration and process control purposes. Additionally, this model offers upper and lower sealing dies sold separately.

CeraTek P/3 Pass-Thru Heat Sealer (12″ & 24″): CeraTek P/3 Pass-Thru Heat Sealers are versatile table-top devices that are ideal for medical pouch sealing and other precision sealing applications. The open-frame structure allows for both lateral and front-to-back pass-through capabilities and can seal the pouch at any depth, making it perfect for header bags that require a secondary seal. Optional features include recipe storage, a bar code scanner and pouch sensors for alignment verification.

CeraTek TA24-ASG/1 Heat Sealer: CeraTek TA24-ASG/1 Heat Sealers come in a 24-inch model with eight independently controlled sections along the heated upper jaw’s length. A 1/8-inch space between each temperature zone decreases heat transfer effects. This device also contains a resettable digital cycle counter and a foot switch to activate the start of the cycle.

CeraTek TA4-GL/1 Heat Sealer: CeraTek TA4-GL/1 Heat Sealers are gradient hot-bar devices with four temperature zones along the length of the heated upper jaw and four identical sections along the lower jaw. Four inches between each zone minimize heat transfer effects from neighboring zones. The temperature of each of the eight sections is independent through a separate controller.

Medical Material Testing Fixtures

Thwing-Albert offers a comprehensive selection of fixtures, grips and accessories to boost the performance of your universal testing equipment.

Catheter Fixture: Medical applications rely on the Catheter Fixture for measuring the force needed to pull tubing out of catheter fittings.

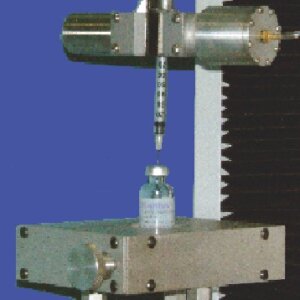

Medical Needle Fixture: The Medical Needle Fixture simulates the force necessary to insert and remove syringes from various bottles used in the medical industry.

Medical Pouch Tear Fixture: The Medical Pouch Tear Fixture utilizes multiple angles to simulate the tear on a medical pouch or bag.

Texture and Strength Testing Machines

Texture and strength analysis play vital roles in the performance of various medical materials, including tackiness, firmness, material strength and the quality of the adhesive.

Handle-O-Meter: Thwing-Albert’s Handle-O-Meter measures a material’s stiffness or hand feel based on the effects of surface friction and flexibility. This instrument is suitable for materials including thin plastic films, textiles and nonwovens.

Gurley 4340 Automatic Densometer & Smoothness Tester: The Gurley Automatic Densometer & Smoothness Tester measures properties such as air permeability, porosity and surface roughness of various sheet-like substrates.

BT-21 Burst Strength Tester: The BT-21 Burst Strength Tester measures bursting strength to perform quality control on medical materials such as nonwovens and barrier materials.

Choose Thwing-Albert for Your Medical Material Testing Equipment Needs

For over 120 years, Thwing-Albert has been a worldwide leader in manufacturing the highest-quality material testing equipment. Contact us today for a quote or request additional information about our instruments for measuring medical materials and other products.

Browse our entire catalog: click here