Equipment for Testing the Ink Layer of Materials

Thwing-Albert offers various testing instruments to measure abrasion resistance and other critical ink rub tests for a comprehensive range of materials including paperboard and corrugated.

RL-RUB-A Ink Rub Tester

The Rycolab RL-RUB-A Ink Rub Tester measures ink abrasion resistance and dirtiness on various substrates, including cardboard, paper, ceramics and more. The tester can operate at four speeds, allowing users to choose the optimal testing speed for their unique product. Faster speeds help maximize test efficiency for substrates such as printed films, plastics and ultraviolet (UV) varnishes.

This tester features an easy-to-use touch panel that controls the cycles and speeds. Optional 2 and 4-pound test weights help speed up the process for high-resistance inks and varnishes. Maximum speeds enable up to 106 testing cycles per minute.

Applicable standards include:

- ASTM F2497

- ASTM F1571

- ASTM D5264

- TAPPI T 830

- FINAT FTM 27

- Sunderland Method

RAS-21 Ink Rub Tester

The Regmed RAS-21 Ink Rub Tester is one of the most popular instruments for measuring abrasion resistance on printed and non-printed materials, including paper, labels, corrugated boxes, folding cartons, films, plastics and similar substrates. This system allows users to choose the speed, number of strokes and base-plate operating temperature required for a specific substrate.

The system’s magnetic clamping system ensures quick and secure fastening on the test sled and base. A safety interlock with plexiglass protection halts movement if opened during the test. The dual rotary test bed offers heatable and non-heatable test surfaces, ensuring smooth and efficient switching between hot and cold testing procedures.

Applicable standards include:

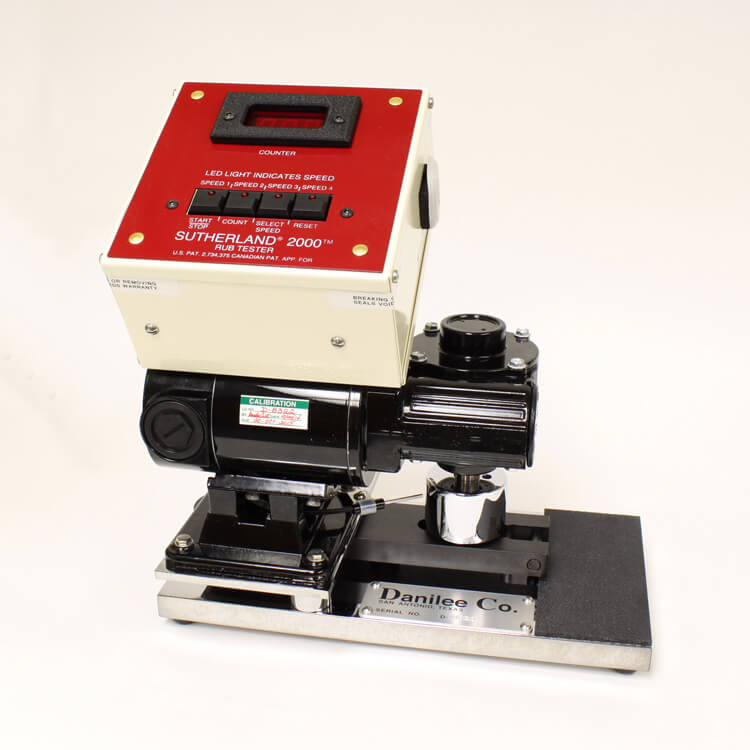

Sutherland Rub Tester

The Sutherland Rub Tester can determine fast and accurate abrasion resistance for various materials using numerous testing methods, including dry rub, wet rub, functional rub, wet smear and wet bleed or wet transfer. The tester features a motor that helps drive a weighted test strip through an arc over printed or coated specimens such as paper, film, paperboard and similar substrates. It also features a digital counter with a fiber optic sensor to ensure the number of rubs and measuring accuracy for each test.

Four speeds enable users to determine the optimal testing rate for each specimen. Higher speeds of up to 106 cycles per minute help increase testing times and efficiency required for materials such as printed films, plastics and UV varnishes.

Applicable standards include:

- ASTM F2497

- ASTM F1571

- ASTM D5264

- TAPPI T 830

- FINAT FTM 27

- Sunderland Method

Choose Thwing-Albert for Your Ink Rub Testing Needs

Since 1899, Thwing-Albert has been a recognized manufacturing leader in advanced testing equipment. Quality control departments, research facilities and educational institutions worldwide rely on our instruments for precise measuring and analysis of various materials. Contact us today to request additional product information or obtain pricing.