- Productos

- Productos por Industria

- Productos por Propiedades

- Abrasión

- Absorción

- Adhesión

- Permeabilidad al Aire

- Peso Base

- Resistencia a la Flexión

- Coeficiente de Fricción

- Compresión

- Aplastamiento

- Rasgado Elmendorf

- Resistencia a la Flexión

- Fuerza de Doblado

- Iimpacto

- Prueba de Tintas

- Frote de Tintas

- “Tack” de Tintas

- Transmisión de Vapor de Agua

- Fuerza de Apertura

- Despegado

- Punción

- Fuerza de Sellado

- Lisura

- Suavidad

- Rigidez

- Tensión

- Espesor

- Vibration

- Resistencia a la Tensil en Húmedo

- ZDT

- Productos por Normas Industriales

- Aparatos Universales de Ensayo de Materiales

- Mordazas y Aditamentos para Aparatos de Tensión

- Aditamento para Coeficiente de Fricción

- Aditamentos para Compresión

- Deflectometer

- Mordazas con Rodillos para Goma

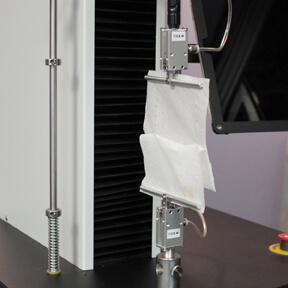

- Cámaras Ambientales

- Extensometers

- Aditamento Finch para Resistencia en Mojado

- Rigidez a la Flexión

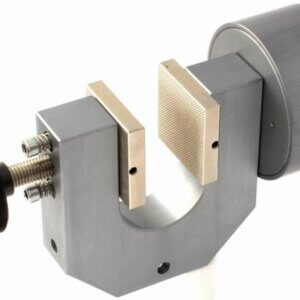

- Mordazas Mecánicas

- Mordazas Mecánicas con Acción de Cuña

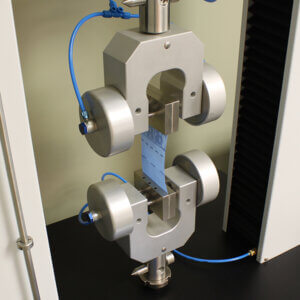

- Aditamentos para Despegado

- Mordazas Tipo Pinza

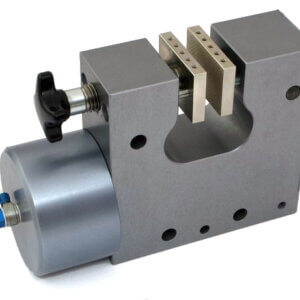

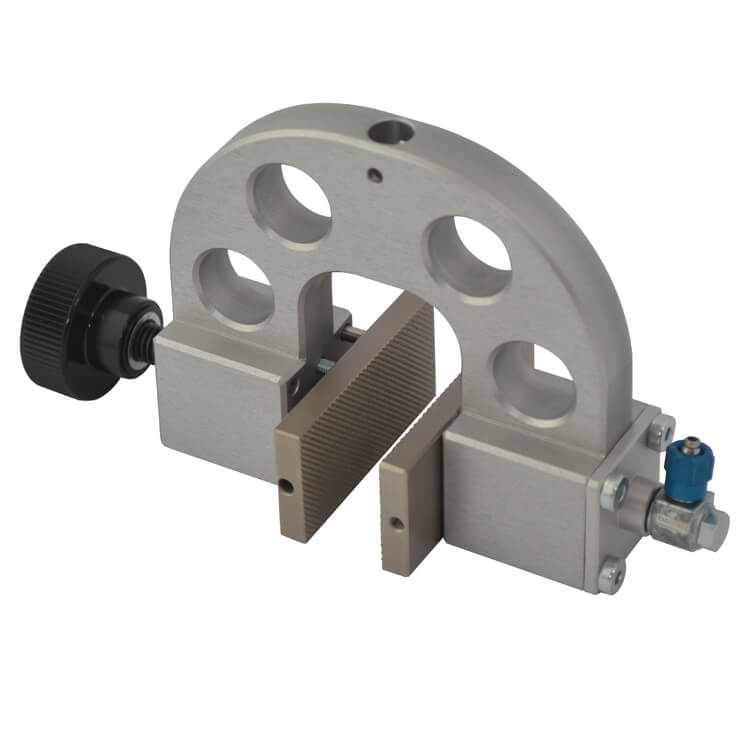

- Mordazas Neumáticas

- Aditamentos para Punción/Estallido

- Aditamentos para Aplicaciones Especiales

- Mordazas para Hilos, Cuerdas, Alambre y Cables

- Cortadores de Muestras

- Softwares de Ensayo

- Equipos Usados

- Servicio

- Videos

- Compañia

- Recursos

- Blog