Thwing-Albert Instrument Company has testing equipment for measuring the physical properties of plastic film materials. Plastic testing equipment allows customers to verify that their materials meet quality standards for product freshness.

Plastic Film Testing Equipment and Accessories

Thwing-Albert offers a wide equipment selection for measuring the physical properties of plastic film materials.

Universal Material Tester

- VantageNX Tensile Testing Machine: The VantageNX Universal Testing Machine can complete a variety of plastic film tests including tensile, elongation, puncture strength, seal strength and coefficient of friction tests. The available grip and fixture options allow the instrument to be set up for a variety of tests to meet quality standards like ASTM, ISO, TAPPI and more.

- QC-3A Universal Testing Machine: For accurate and simplified testing of tensile, coefficient of friction, peel strength analysis and compression tests, the QC-3A Testing Machine is a dependable option that will not require a computer to test plastic films.

Fixtures for Quality Testing of Plastic Film

- Spencer Impact Tester: The Spencer Impact Tester is designed for use with our Elmendorf Tear Tester and provides a means to determine the impact resistance of plastic film in accordance with ASTM D3420.

- Puncture Fixture: Our Puncture Fixture is a pneumatic device that tests the penetration resistance of plastic film. Common configuration in accordance with ASTM F 1306.

- Blocking Fixture: Our Blocking Fixture is available for both our VantageNX and FP-2260 Friction/Peel testers. It measures the degree of blocking — unwanted adhesion — between the plastic film’s layers. This fixture is designed to meet ASTM D3354.

- Browse the full grip catalog for additional options for testing applications including custom solutions.

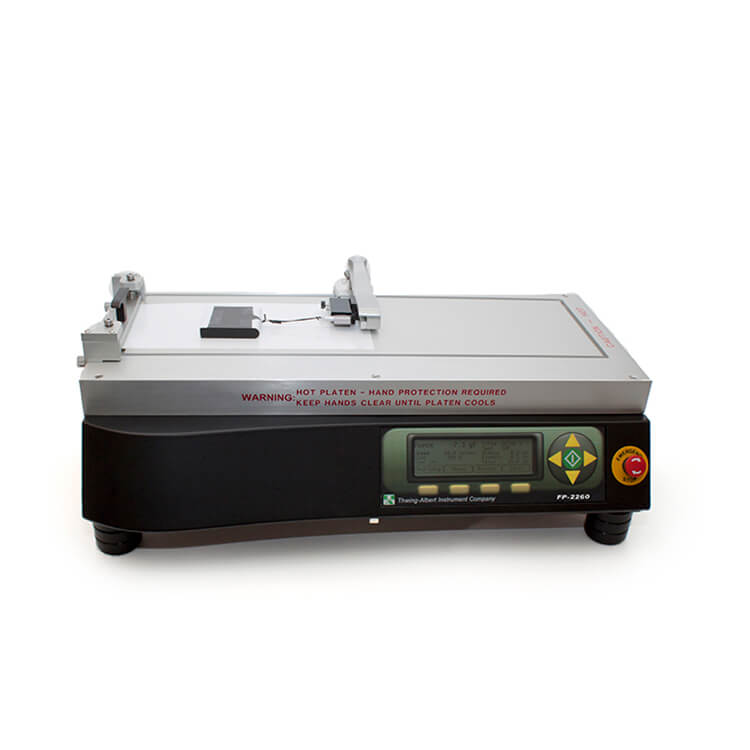

Friction/Peel Testers

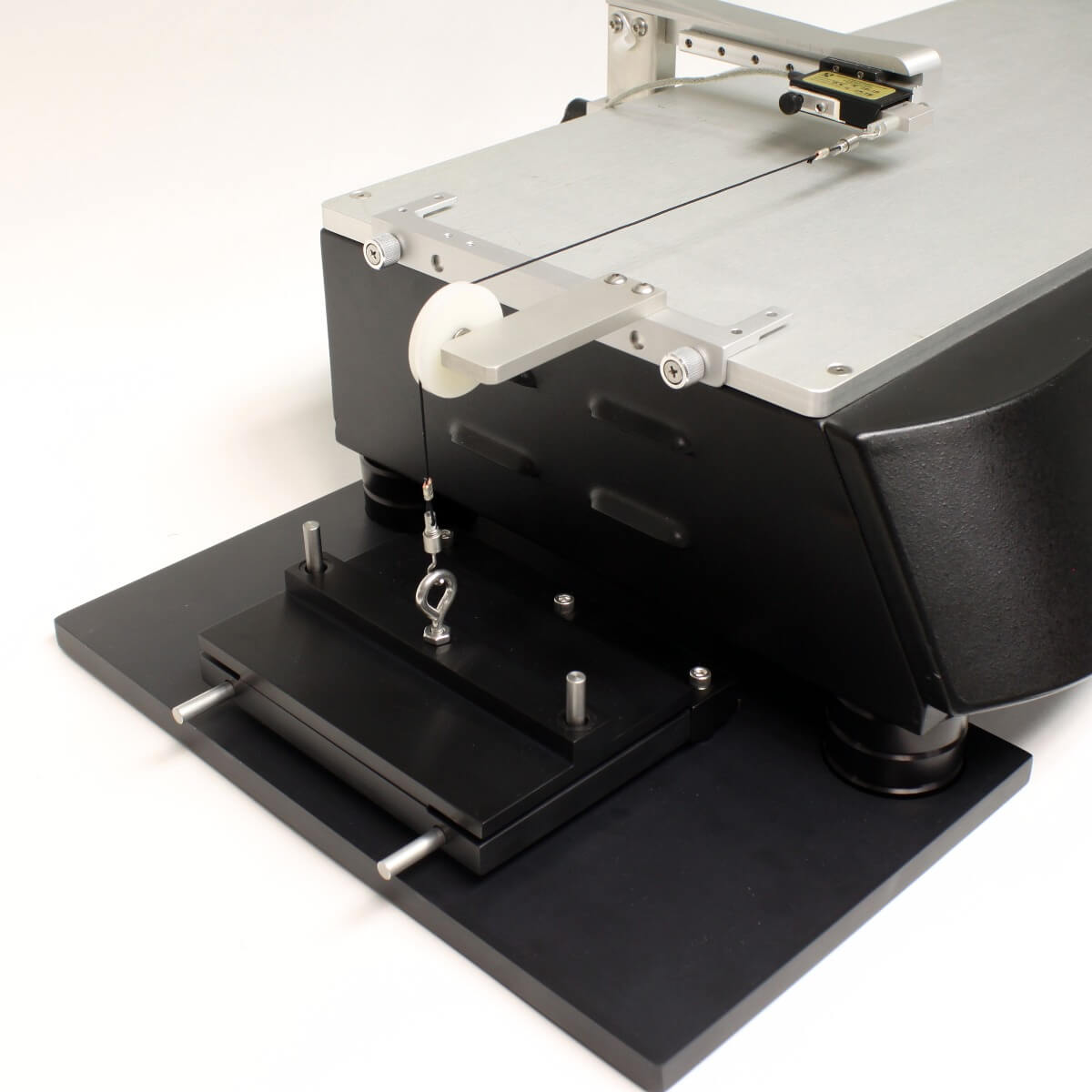

- FP-2260 Friction/Peel Tester: The FP-2260 Tester measures the static and kinetic coefficients of friction, seal strength, peel and tensile strength.

- Heated Platen FP-2260 Friction/Peel Tester: The heated platen tester offers the same features as the FP-2260 Tester, plus a heated platen to test plastic film at elevated temperatures.

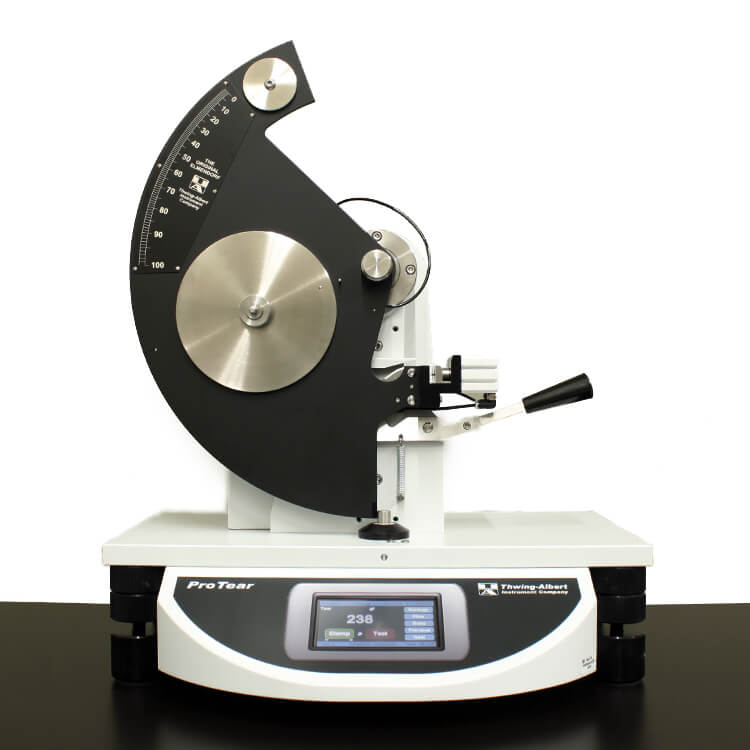

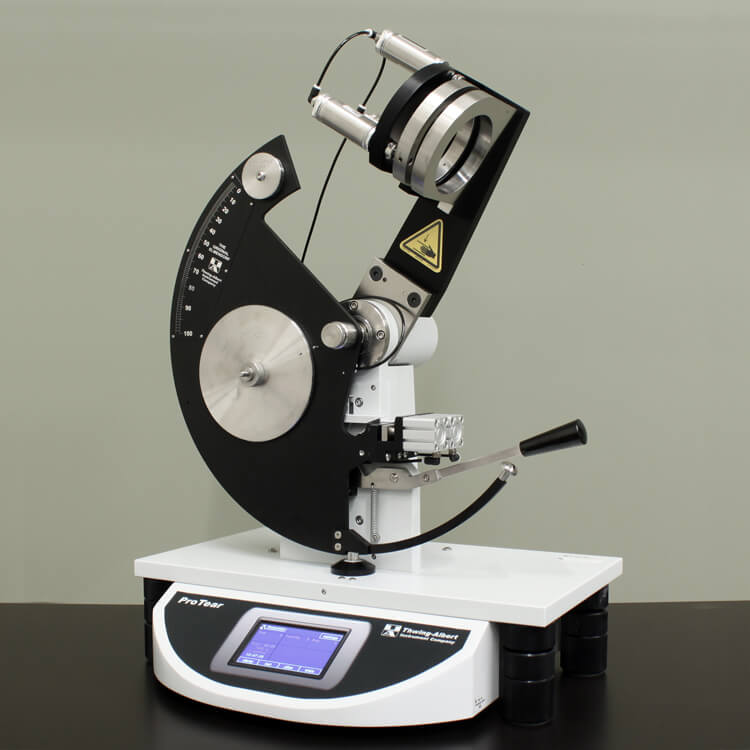

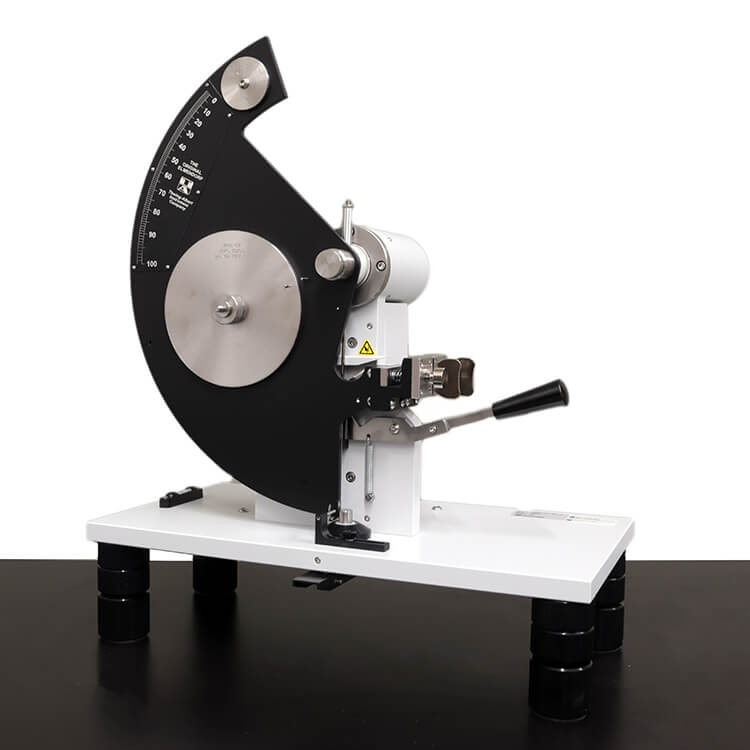

Tear Resistance

- Electronic Elmendorf ProTear: The Electronic ProTear device evaluates the tear resistance of plastic film using pendulums and augmenting weights.

- Mechanical Elmendorf: Our Mechanical Elmendorf is the mechanical version of the ProTear machine. It measures tear resistance in plastic film.

Thickness

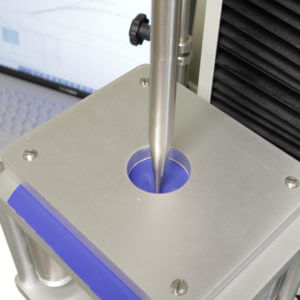

- ProGage Thickness Tester: The ProGage Thickness Tester measures plastic film thickness. Its precision micrometer is highly accurate.

Heat Sealers

- CeraTek ASL/1 Heat Sealers: The ASL/1 Heat Sealer has an open back frame and upper and lower heated jaws. We have 12-inch and 24-inch models available.

- CeraTek P/3 Pass-Thru Heat Sealer: The Pass-Thru Heat Sealer by CeraTek is a tabletop bar sealer for precision sealing. The open-frame design allows packages of any size to pass through. We have 12-inch and 24-inch models.

- CeraTek Blister Heat Sealer TA808/1: The TA808/1 Heat Sealer is a laboratory sealer pneumatically operated for experiments and quality control. The temperature, pressure and sealing time can be adjusted for accurate testing.

Other Testing Equipment

- Taber Abraser (1700/1750): The Taber Rotary Abrasion Tester subjects plastic film to rub wear to determine its abrasion resistance at all angles.

- Water Vapor Transmission Test (WVTR):WVTR cups provide a means to measure the amount of moisture that can pass through a film layer over a specific period of time under controlled environmental conditions.

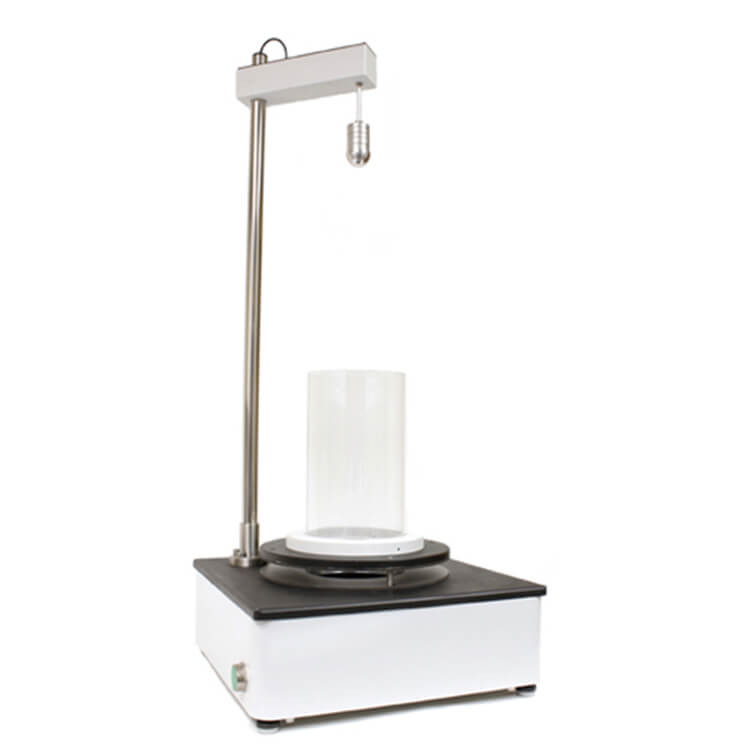

- Dart Impact Tester: The Dart Drop Impact Tester is designed to measure a material’s ability to withstand impact in accordance with ASTM D1709.

Sample Cutters

The ability to prepare test specimens accurately, efficiently, and safely yields repeatable test data and facilities testing.

- Alfa Series Die Cutters: We offer pneumatic and electro-hydraulic die cutters that utilize interchangeable steel rule cutting dies to provide a specimen to the exact required dimensions.

- JDC Precision Sample Cutters: The JDC cutter is a twin-guillotine cutter designed to prepare a dedicated width specimen to an accuracy of +/- 0.001”. These are the preferred cutters for tensile test specimens where edge quality is critical.

Contact Thwing-Albert for Plastic Film Testing Equipment Today

Thwing-Albert is a global leader in plastic film testing equipment. If you need reliable equipment to evaluate your plastic quality testing methods, our machines will benefit your operation. Contact us for more information or a quote.