TAPPICon 2025 – Minneapolis, MN

May 4-7

Booth 339

The 180 Degree Peel Fixture is used with Universal Testing Machines (UTMs) to test the peel or stripping strength of adhesive bonds in flexible adhesive materials. The sample is adhered to the 9-inch by 2-inch polished stainless steel plate and held by an upper grip. The sample is peeled off the plate to record and measure its adhesive strength. This fixture adheres to many common industry standards, including ASTM D3330, ASTM D903, ISO 29862 and FINAT 1.

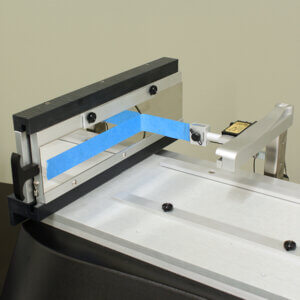

Our 90 Degree Peel Fixture is designed for the Vantage Tester Series and FP-2260 Friction/Peel Tester to test flexible adhesive materials. One end of the sample attaches to the plate, and the upper grip secures the other end of the sample. The peel tester maintains a 90-degree angle to measure peel force. This fixture meets PSTC-1A, ASTM D6252 and ASTM D6862 standards.

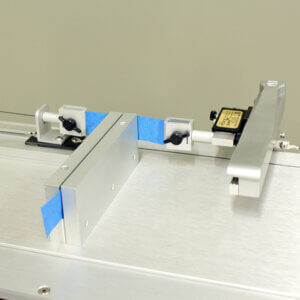

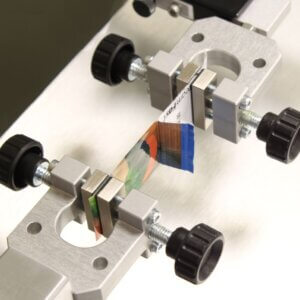

The Delamination Peel Fixture measures the force needed to separate adhesives in card laminations, such as credit and identification cards. This fixture is used with the FP-2260 Friction/Peel Tester and complies with ISO 10373.

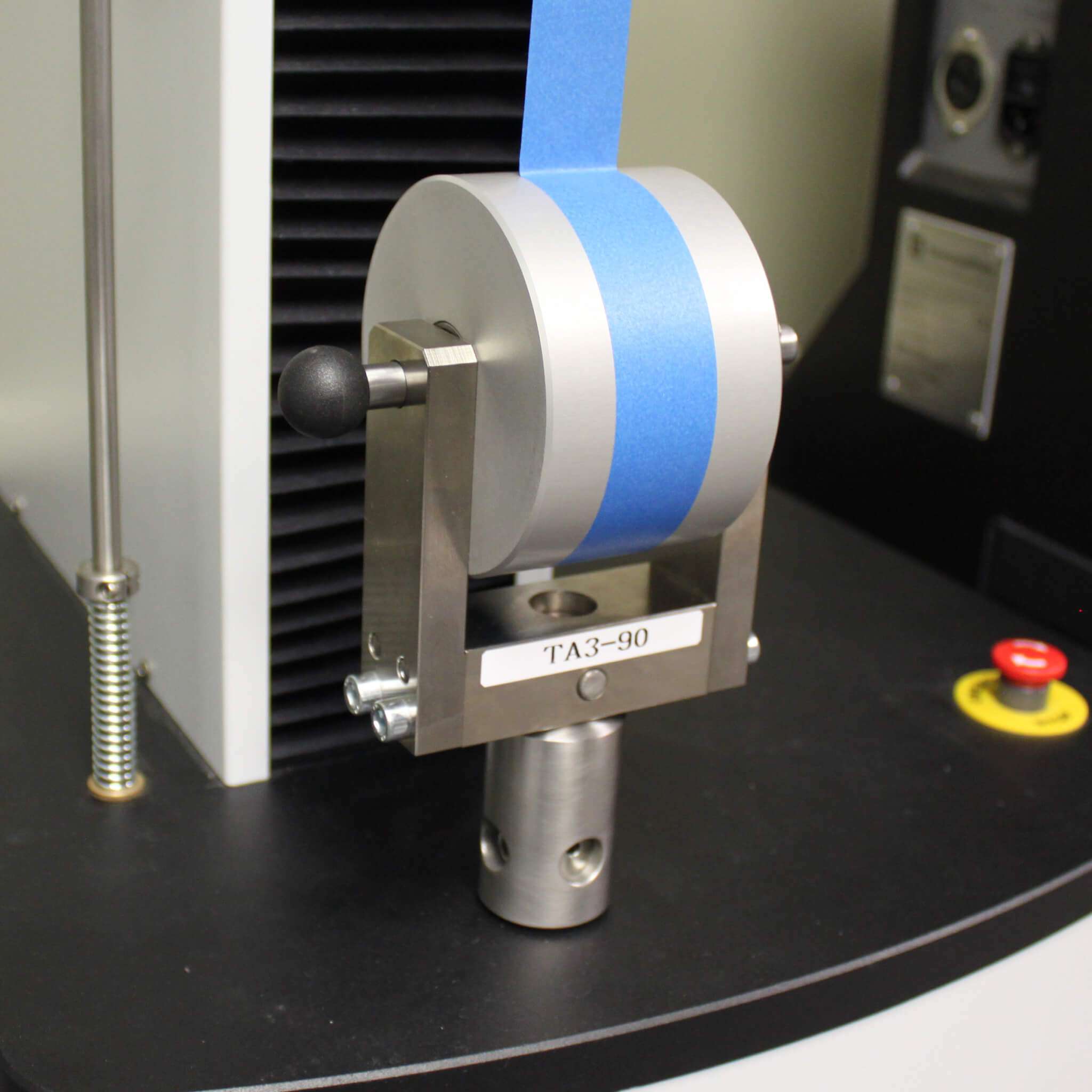

The German Wheel Peel Fixture measures the bond strength and adhesion of plastic and paper films, adhesive foils and films, tapes, and other materials according to DIN 53357. The fixture is used to measures the force required to separate the layers in the material. The sample must be flexible to wrap around the wheel.

Our Heated Platen allows the VantageNX to measure peel strength at temperatures as high as 176 degrees Celsius (350 degrees Fahrenheit) to evaluate the effects of elevated temperatures on the adhesive material. This heated platen can be added to tensile strength testers from Thwing-Albert.

The Loop Tack Fixture from Thwing-Albert performs loop tack testing of pressure-sensitive labels, tapes and adhesives. The sample is looped and lowered until it contacts the stainless steel plate, then the force needed to release the sample is measured. It meets standards such as PSTC 16 Loop Tack, FINAT FTM 9 Loop Tack and ASTM D6195.

The Package Seal Strength Fixture is used to test seal strength for seal or lid removal and cup and tray peel. The vacuum-powered clamping system holds the sample, and the upper grip peels the sample open. The purpose of this peel adhesion fixture is to simulate how a consumer would remove the seal from the product in real-world use.

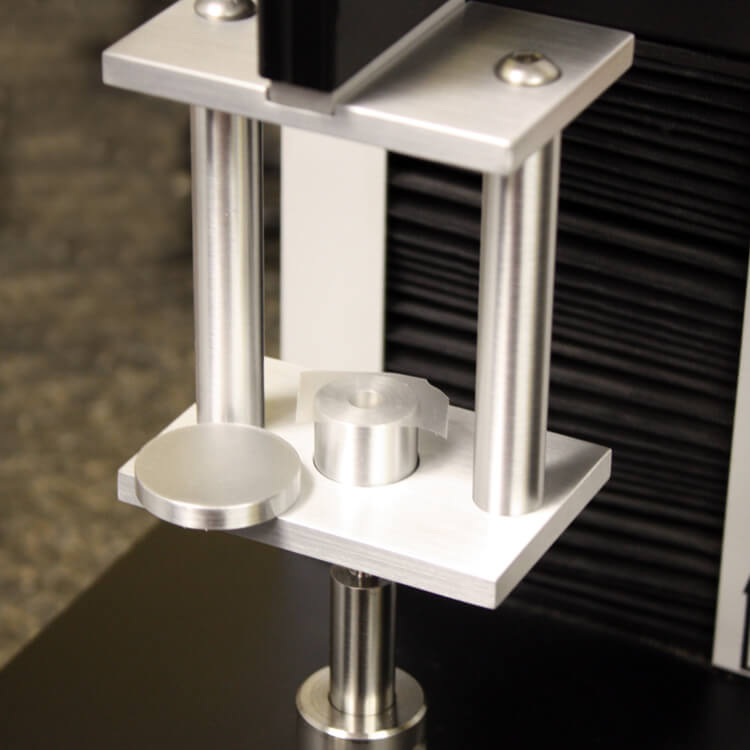

The Probe Tack Fixture uses an inverted probe to test tack in pressure-sensitive adhesives. This fixture fits on the VantageNX UTM, and the MAP4 Materials Testing Software can analyze the tack adhesion data. It meets the ASTM D2979 standard.

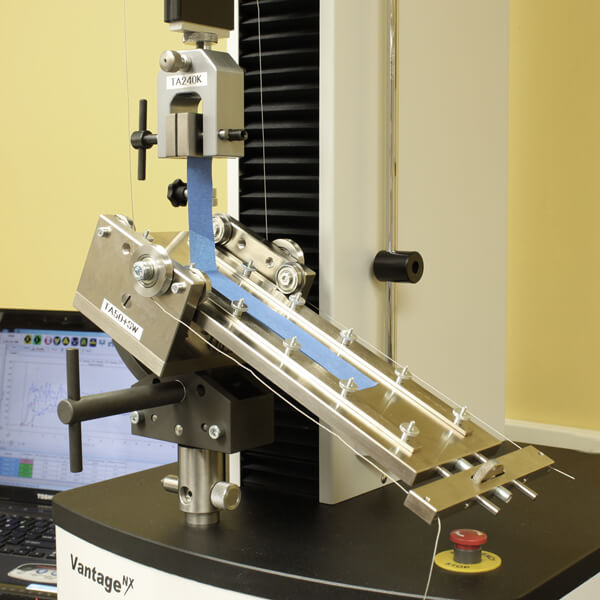

The TA50 Peel Test Fixture measures the bond strength of samples using a sliding table and provides for an adjustable peel angle of ±30 degrees while providing a maximum load capacity of 5 kilonewtons (kN). The sample is attached to the sliding table and the guide wires ensure a smooth, consistent movement while not influencing the measured peel strength.

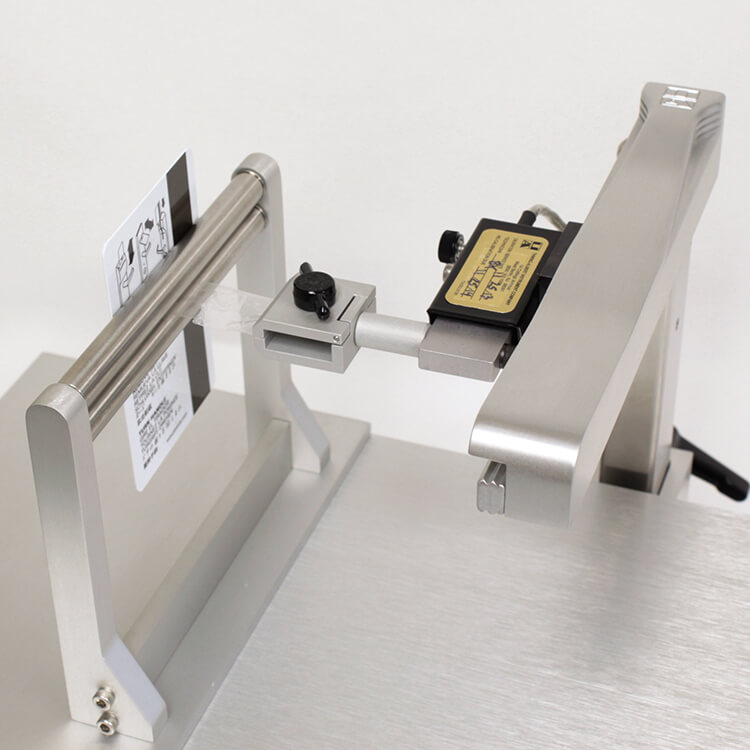

The FP-2260 Friction/Peel Tester is equipped to test 180 degree peel without any special fixtures. Customers can choose to add additional fixtures for testing peel applications including T-Peel, Seal Strength, 90 Degree Peel, and Delamination among others making this a diverse instrument with a compact footprint for testing.

Thwing-Albert has over 125 years of experience in instrumentation for adhesive strength testing. We have the equipment your operations need. Get a quote or more information by contacting our team online today.