Description

The world’s leading software for measuring and analyzing impurities in pulp, paper, and paperboard, Apogee’s Spec*Scan 2000 is acknowledged by mills, research laboratories, and institutions as the easiest, most accurate, and powerful system available. Users rely on the Spec*Scan 2000 to:

- optimize pulp screening and bleaching systems

- maintain cost control for raw materials and pulp mixing

- provide accurate, reproducible results for day-to-day, reel-to-reel dirt content quality control

- control stickies content in recycled fiber

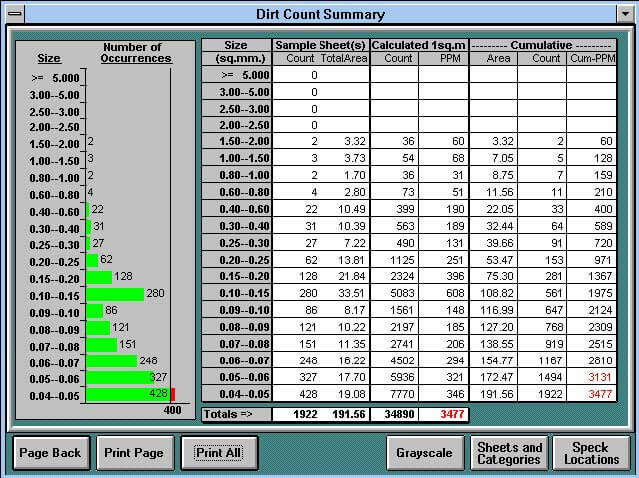

Spec*Scan 2000/2001 is a grayscale image analyzer for pulp, paper, and paperboard. Images are obtained using a desktop scanner and analyzed for specks, dirt, residual ink, pulp shives, printed patterns, and other objects that optically contrast with the paper substrate by their size and reflectivity. The software also measures their size, location, grayscale, and shape and generates reports. The measurements, of both size and reflectivity, are in accordance with TAPPI T-437 which states the estimated equivalent black area of a gray or colored speck is smaller than its actual area in inverse proportion to the intensity of its color contrast with its background.

Spec*Scan uses a simple statistical method to quantify differences in formation quality by analyzing the frequency distribution of the grayscale value of each pixel in the specimen sample image.

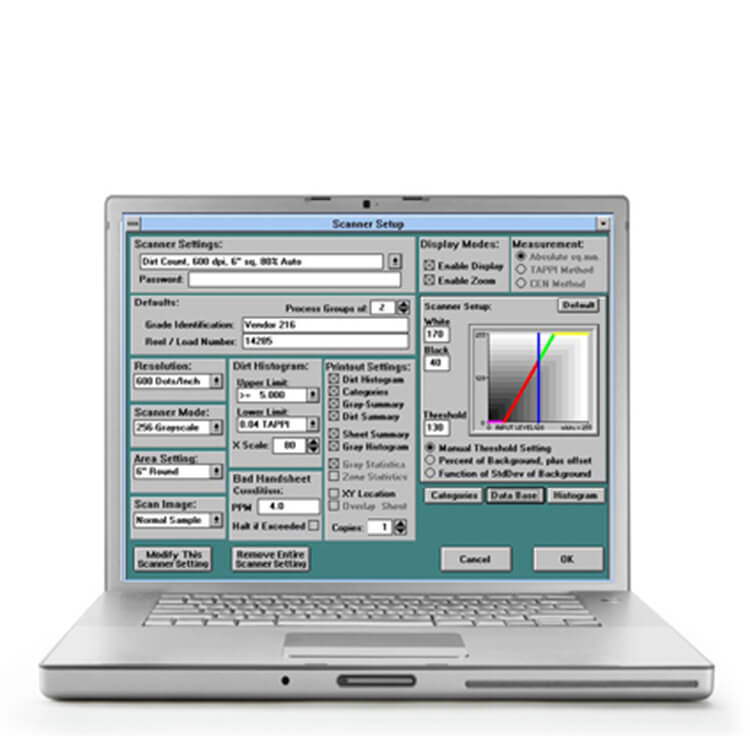

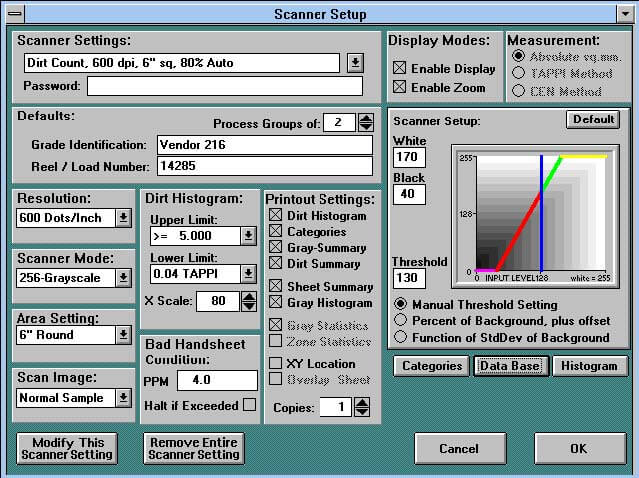

Operation Modes

Scan-to-Screen Mode: View the sample and study it in detail on your computer screen. This mode provides an image zoom, dynamic grayscale adjustment, detailed display of results, speck area histograms, grayscale statistics, speck locations and sizes, sheet summaries, and category listings. All set-up parameters are displayed on a single screen.

Scan-to-Printer Mode: High-speed mode oriented to scanning the samples and printing the results. This mode allows production analysis at the highest possible speed by eliminating much of the operator’s interaction. It prints the same data as in other modes.

System requirements include a standard PC and a high-resolution document scanner. A continuous sheet feeder is available to rapidly test a sample roll.

Ink Jet print quality can be evaluated by attaching a low-end inkjet printer. Spec*Scan then evaluates sheets by printing a specific multi-colored pattern and measuring wicking and bleed properties as a function of the ink migration.

System Requirements

- Intel Pentium

- 500 Meg RAM

- Windows 10 Operating system

- 40 GB of hard drive available

- CD Drive

- SVGA monitor

- Inkjet printer for printability tests or any WINDOWS selectable printer

- Scanners: Epson Expression, Perfection, or GS-series scanner