Description

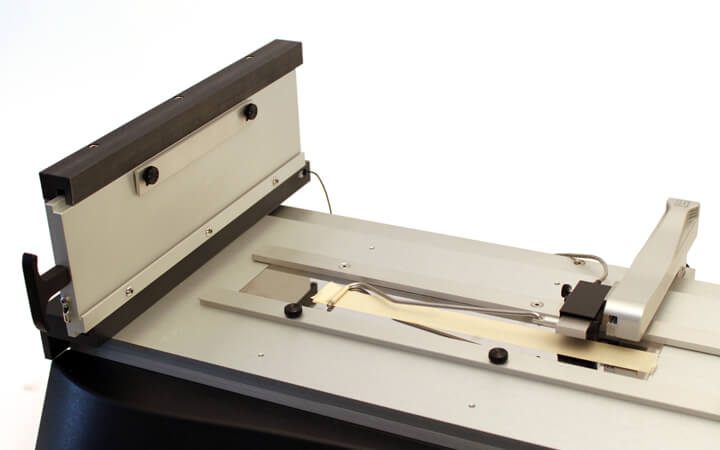

The heated platen allows for testing at elevated temperatures. Ideal for plastic film testing.

Temperature range from:

21C to 204.4C

(70F to 400F)

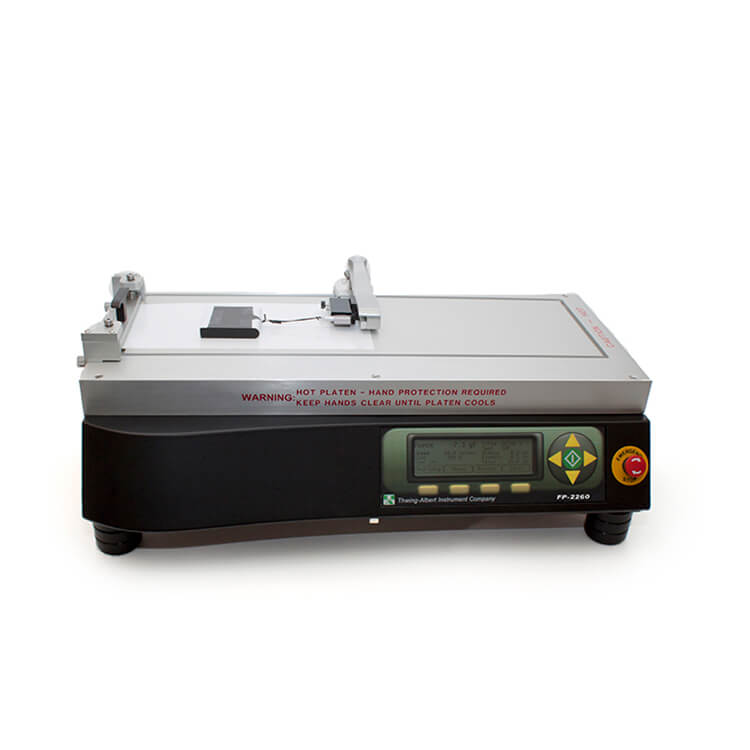

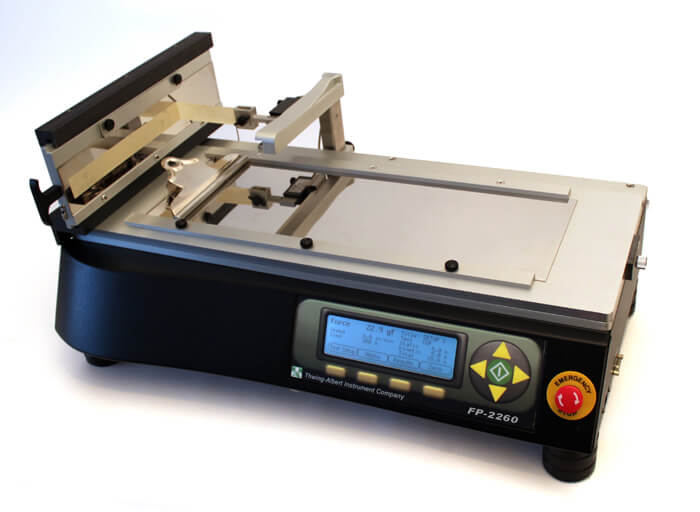

The FP-2260 can measure static and kinetic coefficient of friction as well as run seal strength tests, 180° peel, 90° peel, and T-peel tests. The FP-2260 also offers a tensile test mode to perform lightweight tensile tests up to 10 kg (22 lbf).

Its small bench top design makes the FP-2260 light weight allowing it to be used in a laboratory or setup out on the production floor for offline testing as needed.

Plastic film, adhesives, labels and packaging materials are ideally tested with the FP-2260 heated platen option.

2260-2100

FP-2260 Friction Peel Tester with Heated Platen 110V, 60 Hz

2260-2200

FP-2260 Friction Peel Tester with Heated Platen 220V, 50 Hz

Features:

- Multifunctional membrane keypad

- Easy to read display (240 pixels x 64 pixels)

- Automatic load cell recognition

- Interchangeable .5kg, 1kg, 2kg, 5kg and 10kg load cells

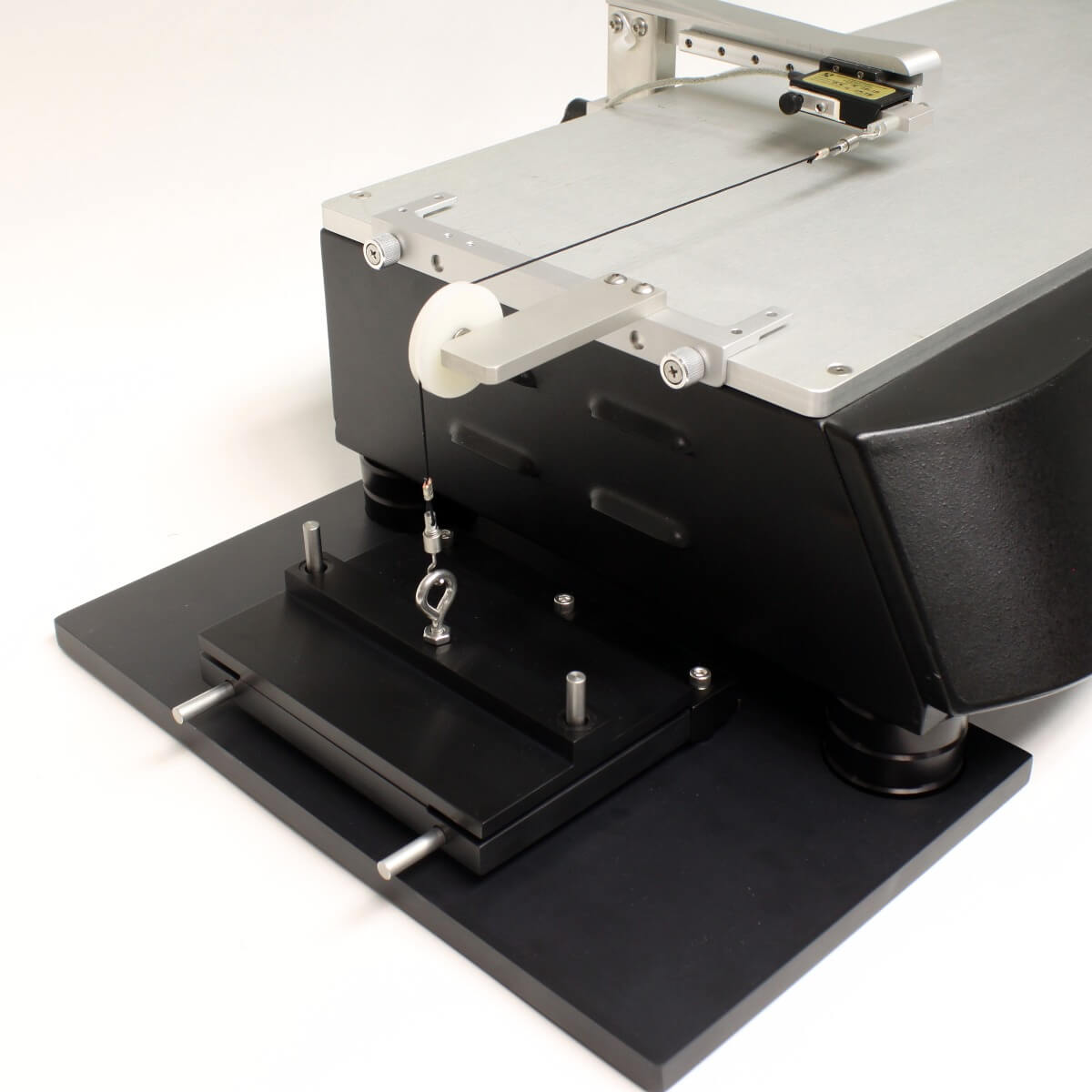

- Adjustable crosshead and load cell (Vertically and Horizontally)

- Automatic Return of the crosshead

- 14″ of Crosshead travel

- Store 128 tests each for COF, Peel and Tensile

- USB and RS-232 Data Communication Port

- Available test area 225mm x 350mm

- Electronic over travel switches

- Selectable force units [g, kg, lbf, oz, N]

- Preset industry standard test method storage

- Ability to save customized test setups

- Industry standards:

ASTM D1894 (COF for Plastics)

ASTM D4521 (COF for Corrugated/Fiberboard)

ASTM D2534 (Coefficient of Kinetic Friction for Wax Coatings)

ASTM D6862 (Standard Test Method for 90 Degree Peel Resistance of Adhesives)

ASTM D6252 (Standard Test Method for Peel Adhesion of Pressure-Sensitive Label Stocks at a 90° Angle)

ASTM D3330 (Peel Adhesion for Pressure Sensitive Tape 180°)

ASTM D1876 (Standard Test Method for Peel Resistance of Adhesives – T-Peel Test)

ASTM F88 (Seal Strength for Flexible Barrier Material)

AFERA: 4001 P11

FINAT: FTM 1-6, 10, 11

ISO 6383 (Tear Resistance of Plastic Films)

ISO 8295 (COF for Plastics)

PSTC: 101 (A, B, C, D, E, F), 4, 15, 55

TAPPI T816 (COF for Corrugated and Paperboard)

TAPPI T549 (COF for Uncoated Writing & Printing Paper)

TLMI: L-IA1, L-IA2, L-IA3

and more…

The FP-2260 utilizes a multifunctional keypad which allows users to easily navigate through the menu options. The crosshead and the load cell are adjustable to allow ease of use when changing test set ups. The system also offers the ability to test to a specific distance or a specific time. The FP-2260 comes standard with the auto return/stop option at the end of a test.

When selecting a COF tester one FP-2260 advantage is the large front panel display screen. The front display is 240 pixels x 64 pixels and is designed for readability by the operator. The memory capacity on the FP-2260 can store up to 128 individual tests for each mode (COF, Peel, Tensile).

For added versatility the FP-2260 offers optional accessories to add testing options:

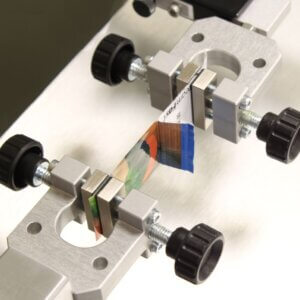

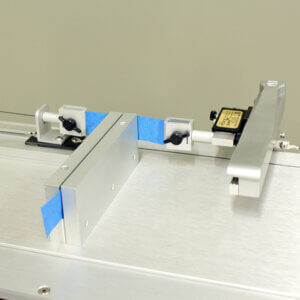

- Low capacity tensile – manual and air operated grips for seal and tensile tests

- Standard and Custom COF sleds

- 90°/180° peel fixture

- T-peel fixture

- Tray peel fixture

- Delamination test fixtures

- Heated Platen for testing at elevated temperatures up to 350° F

Software Option:

- MAP4 Software provides unlimited testing capabilities with built-in test methods that can be customized by the end user. This software allows for extensive data analysis to evaluate materials.